Factory Price Plastic Injection Molding Manufacturing Companies

Product Overview

- JSJM plastic injection molding manufacturing companies are supervised by professionals with extensive industry experience.

- Engineered to save cost and labor, widely used in various fields, with a good industry reputation.

Product Features

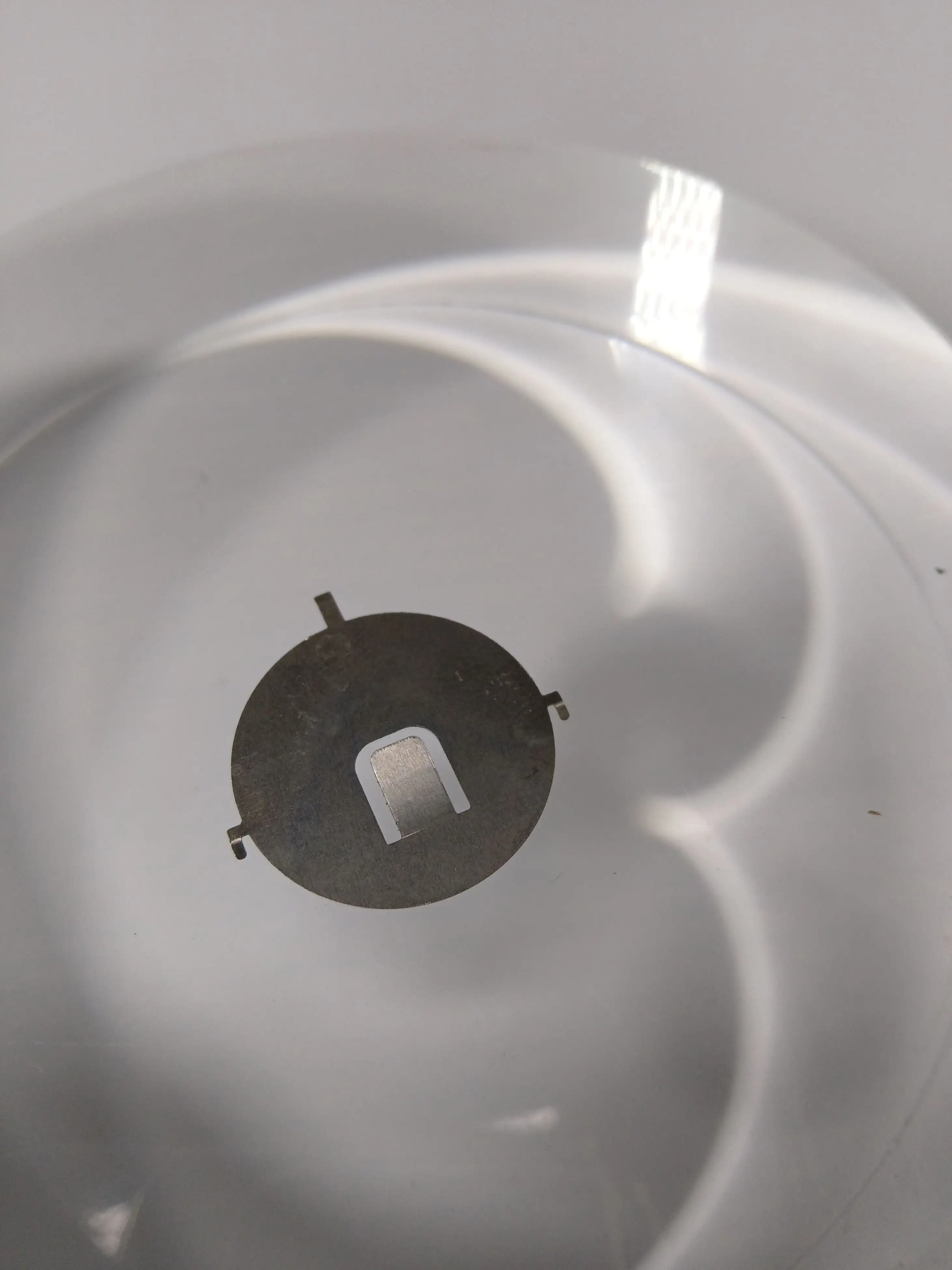

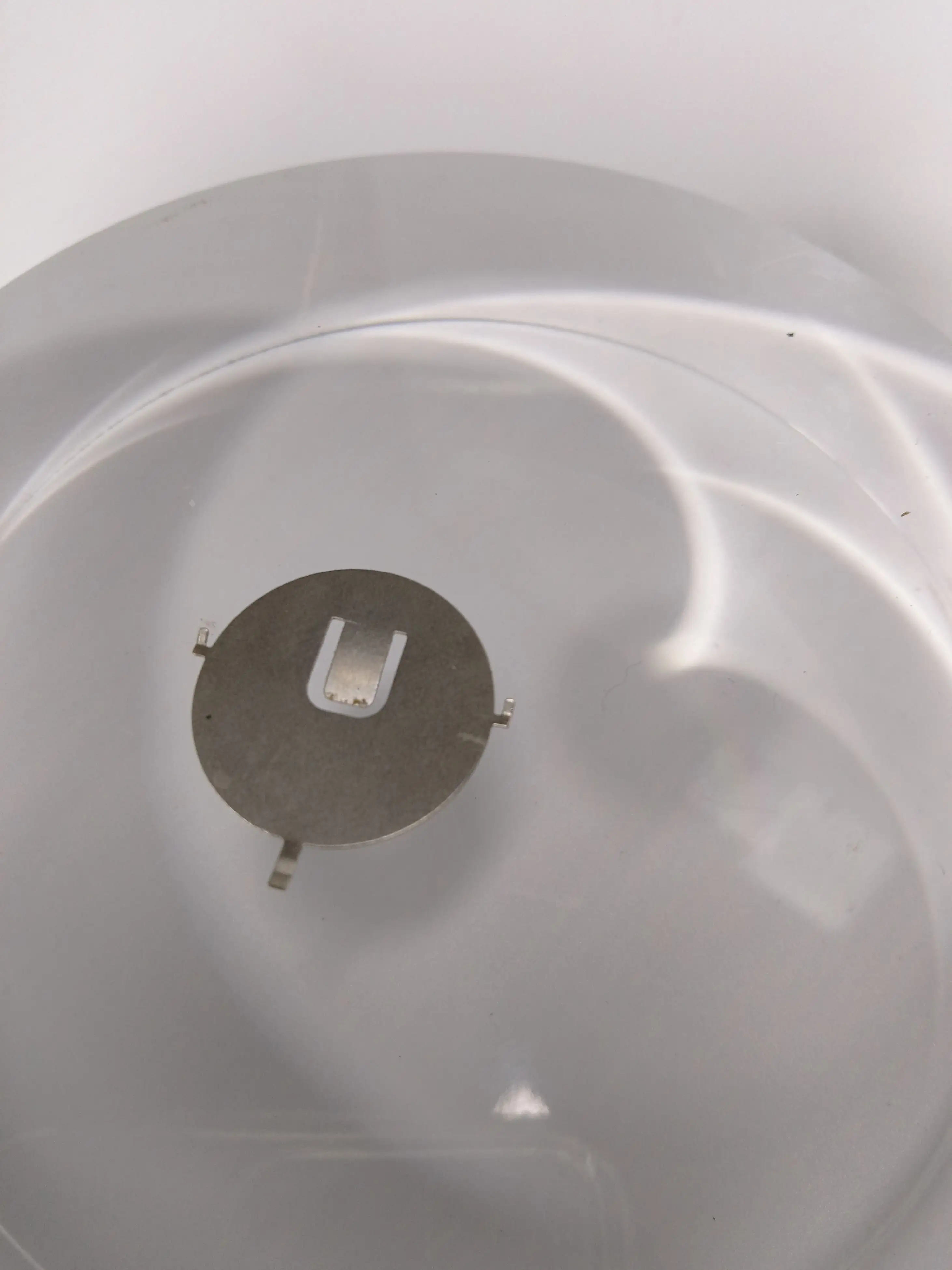

- Manufactured using injection and stamping molds, with a reasonable buckle design for metal and plastic connection.

- Structural and design engineers provide samples for customer feedback and final design decisions.

- Materials come with ROHS and REACH certifications, with a 20-25 day mold production time.

Product Value

- Assembling products in China can increase value and reduce shipping costs.

- Skilled team provides reduced labor, logistics, and administrative expenses for customers.

- Full range of services from design to packaging, with high-quality products and efficient assembly.

Product Advantages

- Professional one-stop assembly service for over 12 years.

- More than 300 people assembly team and 10,000 square meters of assembly workshop.

- Shipping costs for empty parts are the same as finished products.

Application Scenarios

- Ideal for New Energy Automobile Industry, custom plastic parts with various surface treatments available.

- Certified with quality management systems, IATF16949:2016, IS0 9001:2015, ISO 14001:2015, ISO45001:2018.

- Services include injection, mold design, CNC machining, quality control, and product packing.

+86 13433648351