Professional manufacturer of more than 3,000 consumer electronics products!

● What is the significance of injection molding, precision stamping and industrial connectors for the consumer electronics industry?

● What are the advantages of Precision Mold as a Tier 1 supplier of iRobot® in the consumer electronics industry?

● What do we invest in the electronics industry?

● What products in the electronics industry are we currently involved in manufacturing?

What is the significance of injection molding, precision stamping and industrial connectors for the consumer electronics industry?

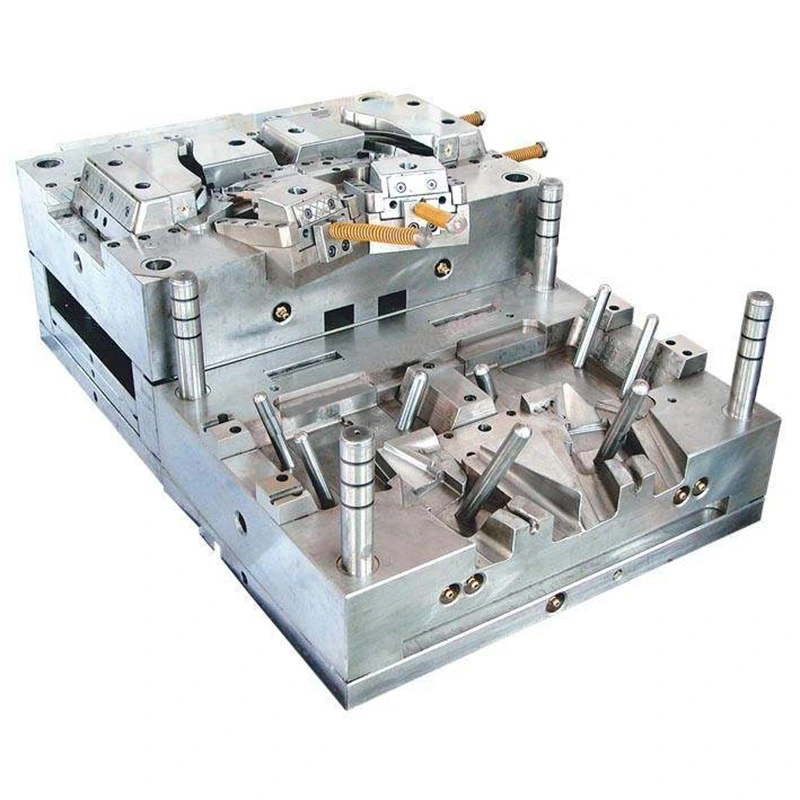

Injection molding is of great importance to the consumer electronics industry. It is a common manufacturing process, and in the consumer electronics industry, injection molding is widely used to make parts such as housings, panels, and buttons.

First, injection molding can provide high-quality appearance for consumer electronics products. Shell, panel and other parts through injection molding can have a smooth, uniform surface, making the appearance of the product more beautiful and attractive. The injection molded parts have good abrasion resistance and insulation properties. Consumer electronic products usually need to withstand a long time of use, housing, buttons and other parts of the durability and insulation performance directly affect the service life and safety of the product. Parts manufactured by injection molding can meet the needs of products in different environments and improve the reliability and stability of products. Injection molding has lower production costs, which can help consumer electronics manufacturers control product costs and improve product competitiveness and market share.

Precision stamping can achieve high-precision parts processing, can achieve micro-size processing on metal materials, to ensure the accuracy and consistency of parts, in line with the requirements of consumer electronics products on the dimensional accuracy of parts. Secondly, precision stamping can achieve efficient mass production, through automation equipment and high-speed punching press, can complete large-scale parts production in a short time, improve production efficiency, reduce manufacturing costs. Precision stamping can realize complex shape parts processing. Through flexible mold design and highly controllable processing process, various complex shape parts can be processed to meet the diversified needs of consumer electronic product design. Finally, precision stamping can realize the processing of a variety of materials, such as aluminum alloy, copper alloy, stainless steel, etc., to meet specific material characteristics, such as electrical conductivity, thermal conductivity, corrosion resistance and so on.

The significance of industrial connectors for the consumer electronics industry is reflected in the following aspects:

Functional connection and transmission:

Industrial connectors, as an important part of electronic equipment, are responsible for connecting different electronic components, such as circuit boards, sensors, display screens, etc., to achieve signal, power or data transmission. Industrial connectors can ensure the effective communication between the various functional modules inside the consumer electronics products to ensure the normal operation of the products.

Reliability and stability:

High-quality connector design can ensure that the connection is stable, not easy to loose, to avoid the connection failure caused by equipment function failure or performance degradation, improve the service life of the product and user experience.

Design and manufacturing technology:

Industrial connector design and manufacturing technology such as precision injection molding, metal stamping processing, surface coating technology, etc., to ensure that the product has good durability, corrosion resistance and anti-interference ability.

Safety and environmental protection:

high-quality industrial connector design can ensure that there will be no overheating, short circuit and other safety hazards during use, while the use of environmentally friendly materials and processes can reduce pollution to the environment.

Our Advantages

We focus on the needs and characteristics of the electronics industry and provide customized products and services.

We have a perfect after-sales service system, timely solve the problems encountered by customers in the process of use. Provide professional technical support and can help customers solve technical problems in production, improve production efficiency and enhance partnership.

What do we invest in the electronics industry?

Upgrade of production equipment and technology:

Invest in the purchase of advanced mold manufacturing equipment, precision machining machines and automated production lines to improve production efficiency and product accuracy. Our injection molding machines range in tonnage from 80 tons to 560 tons. Our press machines range in tonnage from 20 tons to 300 tons.

The introduction of advanced precision injection molding, precision stamping and other molding technology, as well as high-precision cutting, grinding, polishing and other post-processing technology, to ensure the stability and reliability of product quality.

R&d and innovation capacity enhancement:

Set up a dedicated research and development department and invest research and development funds for the development of new molds, materials and processes to meet the electronics industry's demand for high performance and high reliability products.

Strengthen cooperation with universities and scientific research institutions, introduce external research and development resources, and promote technological innovation and industrial upgrading.

Improvement of quality control and inspection system:

Invest funds to establish a strict quality control system, including raw material inspection, process control, finished product testing and other links to ensure the stability and consistency of product quality.

The introduction of advanced testing equipment and instruments, such as three-dimensional measuring instrument, spectral analyzer, etc., to improve the detection accuracy and efficiency.

Talent Training and team building:

Invest resources to train talents with professional skills and industry experience, including mold designers, process engineers, quality management personnel, etc.

What products in the electronics industry are we currently involved in manufacturing?

+86 13433648351