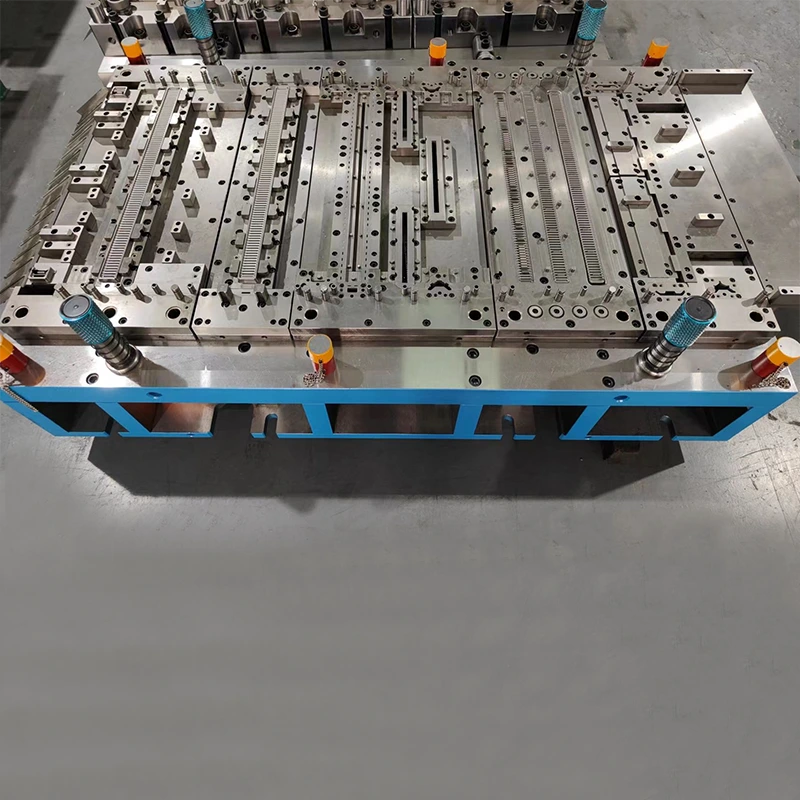

Precision stamping mold continuous stamping die for Vehicle

MOQ: 1 PCS

Application: New Energy Vehicle Industry

Payment: T/T, L/C, Paypal

Delivery Time: 15-20 days for sample, 5-7 days for shipping the mold out (Negotiable)

Place Of Origin: Dongguan city, Guangdong province, China

Product Description

● Efficient production: Continuous stamping die can carry out continuous automated production, each stamping can complete a number of complex parts at a time, reduce the intermediate transfer process. The production cycle is only 1.5s, which improves the production efficiency!

● Precision control: In the continuous stamping process, the position relationship between each station and the stamping force and other parameters can be precisely controlled to ensure the high consistency of the size and shape of the parts.

● High material utilization rate: continuous stamping makes reasonable use of raw materials, greatly reduces material loss, and improves material utilization rate. We ensure that the tolerance of the mold is up to ±0.001mm.

● Saving manpower: Continuous punching mold can realize automated production, greatly reducing the required manpower and reducing production costs.

● Wide range of application: continuous stamping die can be used to produce a variety of complex shapes of metal sheet parts, suitable for automotive, home appliances and other industries.

JSJM strives to become a professional precision mold manufacturer to produce safe and reliable products for customers!

Product parameter

|

Brand Name |

JSJM |

|

Product Material |

CRS, Stainless stell, Copper, Brass, Aluminum |

|

Product |

Vehicle Mould |

|

Mold material |

Die plate |

|

SKD11,Stripper plate |

P20 or As specified by the customer |

|

Application |

Consumer Electronics Industry |

|

Technology |

Progressive, sheet metal stamping punch mould tool |

|

Mould life |

3000k shots |

|

Certification |

ISO9001/IATF16949/ISO45001/ISO14001 |

|

Process |

Wire Cut |

Packaging & Delivery

|

Package size(Wooden Case) |

80*70*70 cm;1 tooling 1 wooden case |

|

Package Type |

Wooden Case |

|

Single gross weight |

150 kg |

|

Lead Time |

5-7 days |

Product advantages

Our services

+86 13433648351