Plastic Injection Moulding Suppliers by JSJM

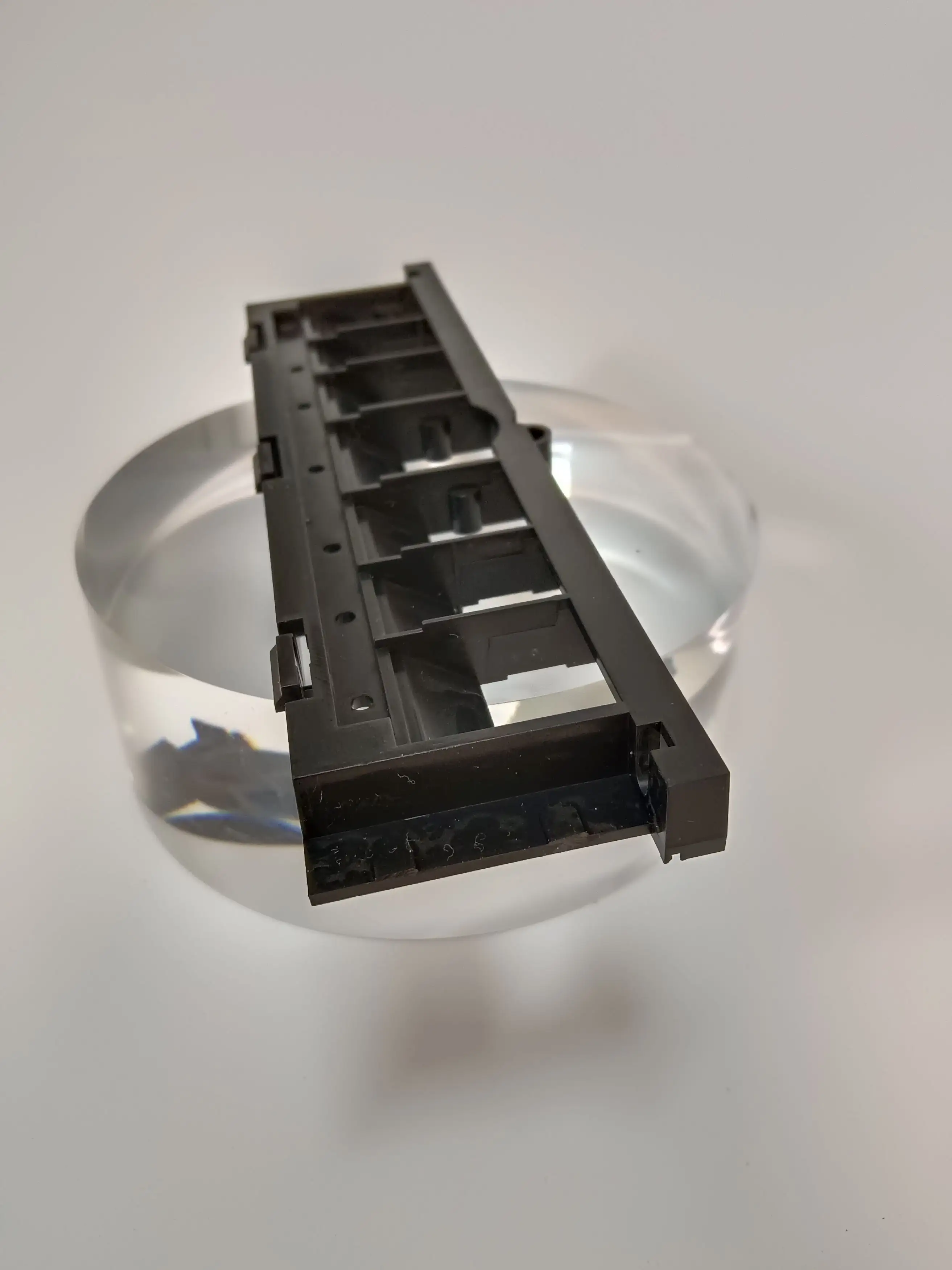

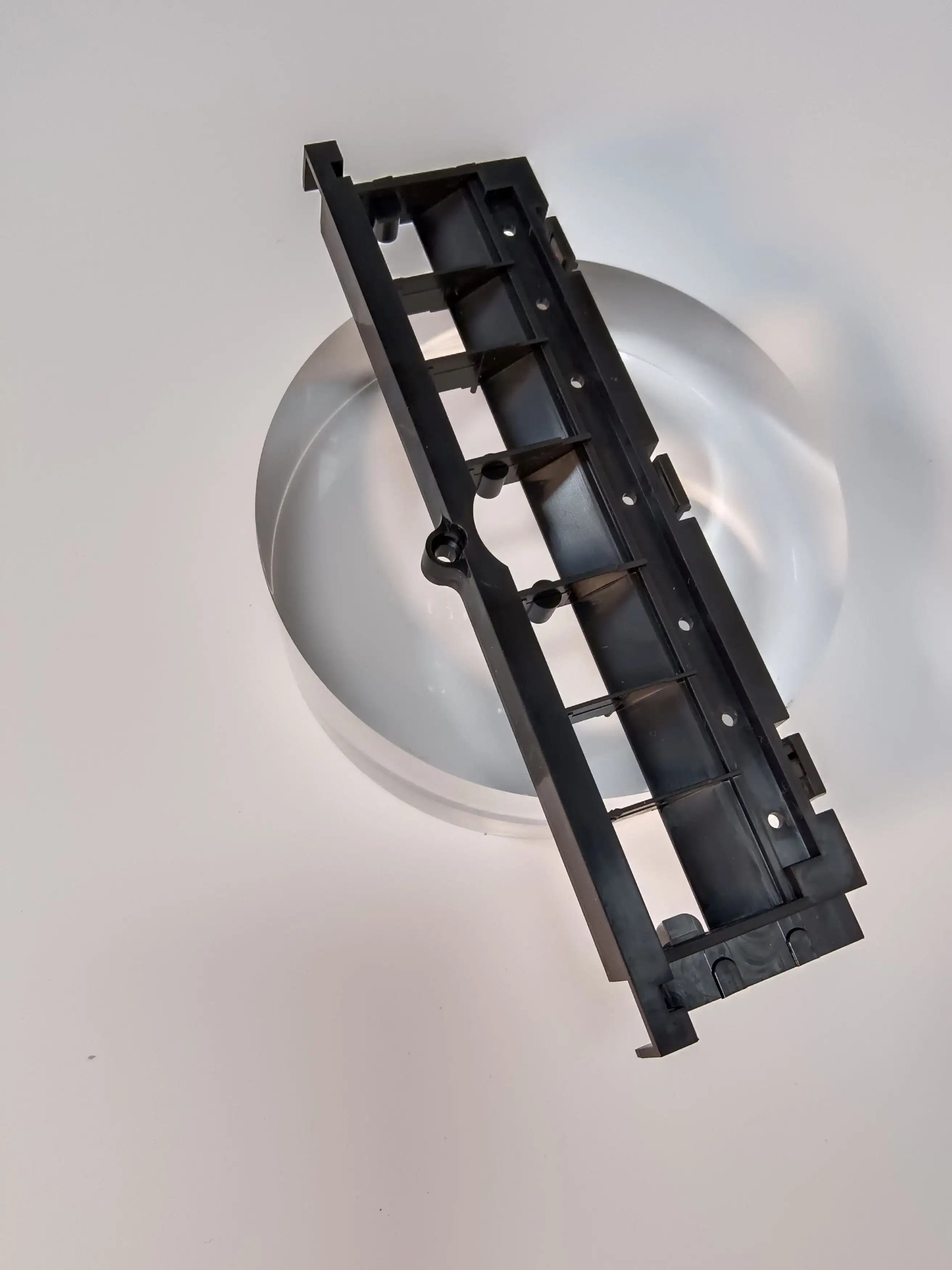

Product Overview

- JSJM plastic injection moulding suppliers are designed with aesthetics in mind, offering outstanding performance, durability, and usability.

- The product is produced with quality assurance using advanced machines by JSJM.

Product Features

- The plastic injection moulding suppliers serve as connection brackets for consoles, with extensive experience in providing effective buckle solutions.

- A one-hole mold is used for products with low annual consumption to save costs.

- Expertise in injection moulded structural parts with quality recognized by customers.

- Materials come with ROHS and REACH certifications, with the option to change colors according to customer needs.

- Fast mold production time of 15-20 days, providing samples for customer testing.

Product Value

- JSJM plastic injection moulding suppliers offer high-quality and cost-effective solutions for customer needs in the new energy automobile industry.

- Customizable sizes and colors are available, with options for OEM/ODM services.

- The company holds certifications for quality, environmental, and occupational health and safety management systems.

Product Advantages

- JSJM has a strong focus on quality and innovation, aiming to become a world-class company with international competitiveness.

- Professional teams in R&D, quality inspection, and consultation services provide a strong guarantee for continuous development and customer satisfaction.

- Technical expertise allows for tailored processes and solutions to better solve customer problems.

Application Scenarios

- JSJM plastic injection moulding suppliers are suitable for use in the new energy automobile industry, particularly for car accessories and door inner armrests.

- The products are versatile and can be used in various applications where high-quality and customizable plastic parts are needed.

+86 13433648351