Oem & Odm Plastic Injection Molding Manufacturing Companies Company-1

Product Overview

- The product is a customized processing solution that provides personalized solutions to reduce manufacturing costs and improve competitiveness.

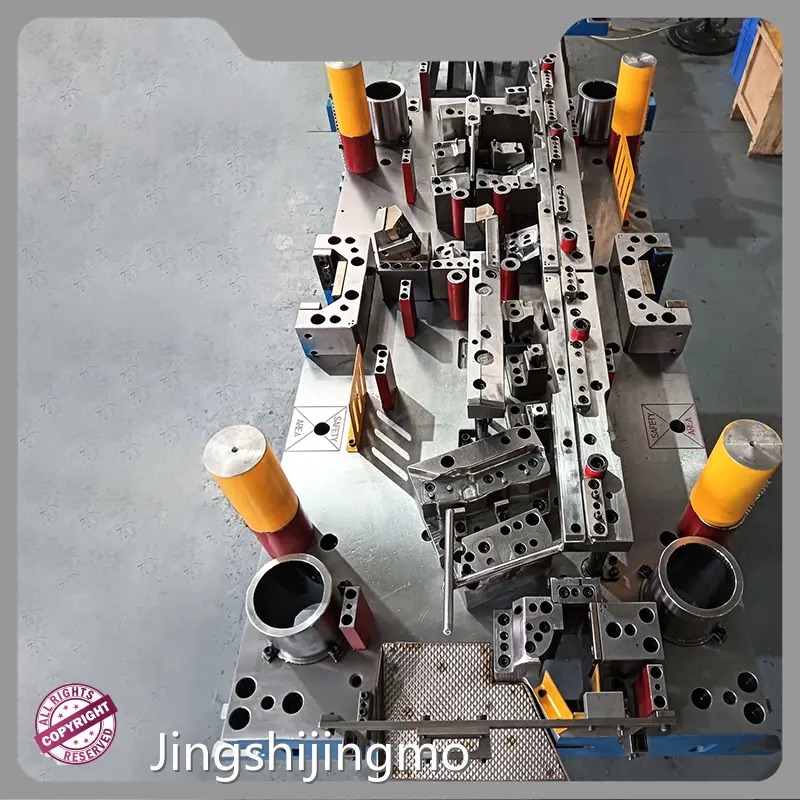

- It uses the latest heat treatment equipment and precision grinding to ensure high mold tolerances and surface finish.

Product Features

- Material options include CRS, stainless steel, copper, brass, and aluminum for vehicle molds in the consumer electronics industry.

- Certification includes ISO9001/IATF16949/ISO45001/ISO14001.

- Process includes wire cut technology with a mold life of 3000k shots.

Product Value

- Fast mold opening cycle, customized metal products delivered within 30 days.

- Free drawings design, free samples for testing, 24-hour online support for problem-solving.

- Various payment methods available, complete quality inspection report provided with each order.

Product Advantages

- Fast mold opening cycle with new molds completed within 15 days.

- Short customized product cycle with delivery within 30 days for up to 1,000,000 pieces.

- Production progress feedback mechanism and 24-hour online support for problem-solving.

Application Scenarios

- The product is widely used in the consumer electronics industry for producing safe and reliable products.

- Transportation advantages include DDP double clearing service and visualization of loading process to ensure timely delivery.

- Quality control is crucial in manufacturing to ensure products meet standards, reduce costs, and enhance competitiveness.

+86 13433648351