Metal Stamping Molds Price List

Product Overview

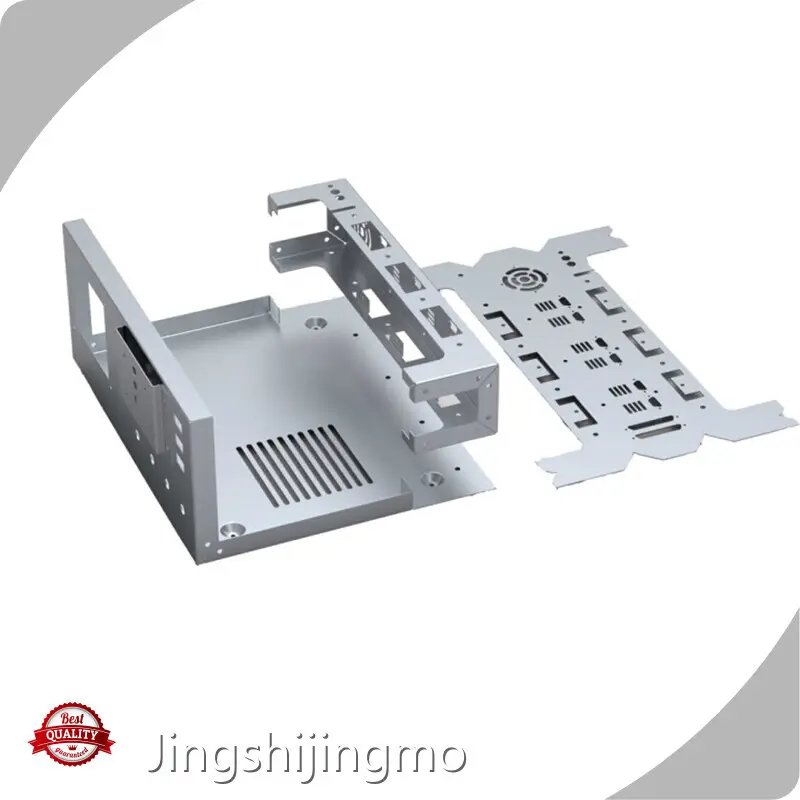

- The product is a metal stamping mold made of 304 stainless steel with a thickness of 2mm. It is a strong metal frame used for mounting PCBA boards during package assembly.

Product Features

- The metal bracket is made of high-quality materials and needs to be electroplated before stamping. The position and size of the hole are crucial for assembly.

- The tonnage of the machine used is 150 tons with automatic testing equipment installed for high product yield.

Product Value

- Automation in the stamping process makes it cost-effective compared to other metal processing technologies.

- The stamping process does not require heating elements, providing an affordable solution for manufacturing needs.

Product Advantages

- Automation after stamping die manufacturing reduces project time and labor costs while maintaining precision in manufacturing complex parts.

- The stamping process is more cost-effective compared to processes like hot metal forging that require heating.

Application Scenarios

- The metal stamping mold can be used in the consumer electronics industry for manufacturing various components and parts.

+86 13433648351