Injection Molded Plastic Products - - JSJM

Product Overview

The JSJM Injection Molded Plastic Products are used inside cameras and are assembled with M2.5 self-tapping screws. They are made with high-quality Polypropylene material and have a production time of 20-25 days.

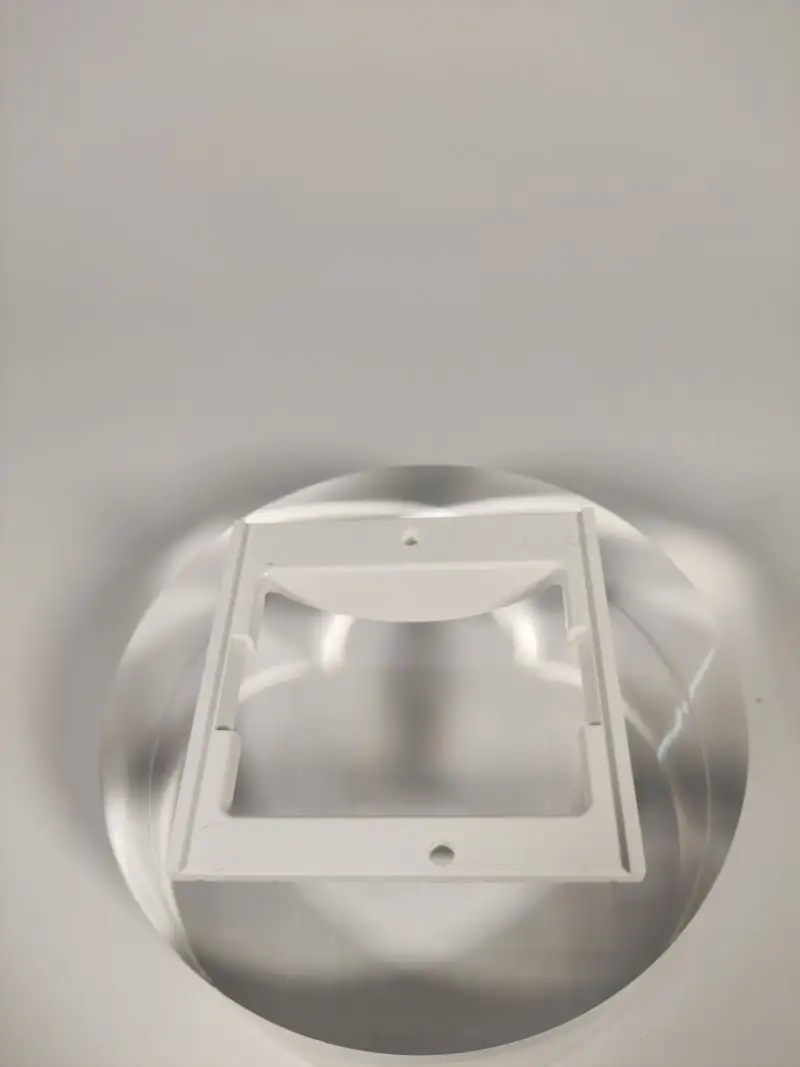

Product Features

The products have a tolerance of ±0.02mm, come in various materials such as ABS and PC, and can be surface treated with plating, pad printing, and more. They have a MOQ of 1 piece and are available in black/white and Pantone color options.

Product Value

The products offer high-quality materials, precision processing, safety, durability, and customized services. They undergo strict quality control measures and have a rapid response team for customer needs.

Product Advantages

The advantages of the product include using high-quality materials, precision processing for dimensional accuracy, safety features, strong durability for harsh environments, and customizations according to customer needs.

Application Scenarios

The JSJM Injection Molded Plastic Products are widely used in the automobile industry. They are designed to meet the personalized requirements of customers and can run stably for a long time in various applications.

+86 13433648351