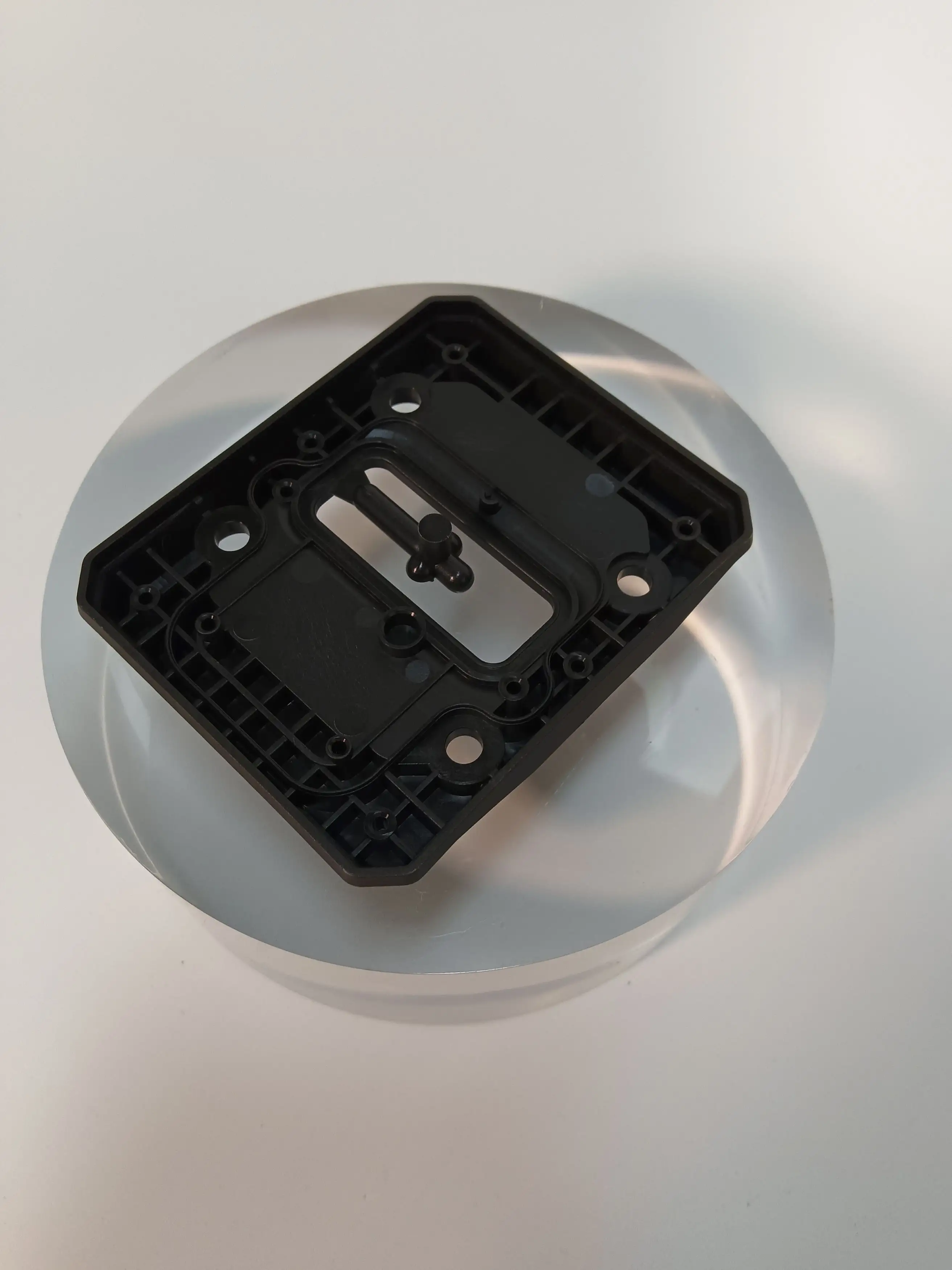

Bulk Productioninjection Molded Plastic Parts

Product Overview

JSJM injection molded plastic parts are precisely measured and tested to ensure precise specifications, with a long service life and durable performance.

Product Features

Adding glass fiber to the plastic increases structural strength, with machine debugging ensuring controlled appearance. Engineering reports address potential problems, and the factory's experience helps improve design.

Product Value

The company can deliver 100,000 products in seven days with two shifts working 24 hours a day, and mold production time is 15-20 days.

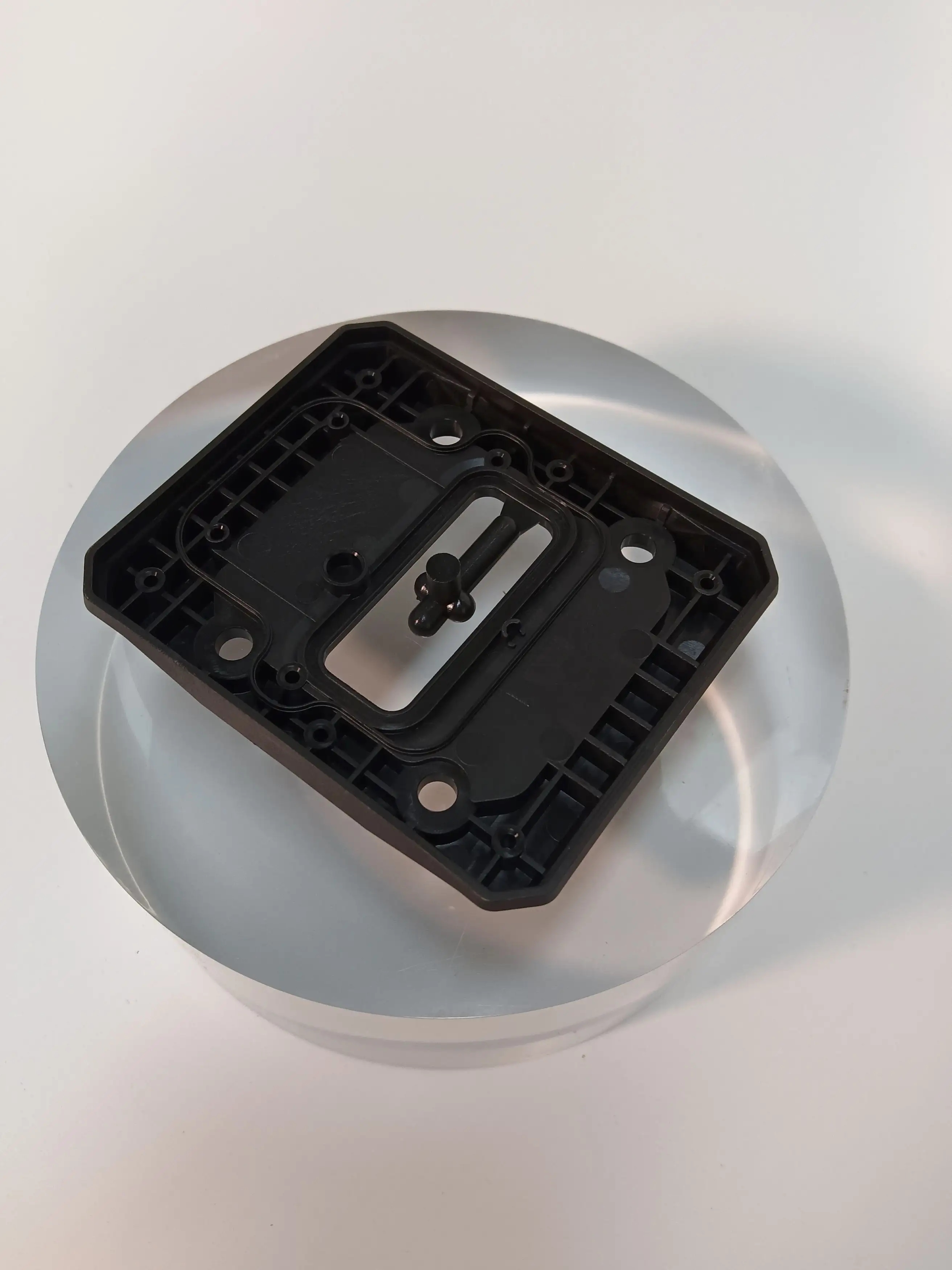

Product Advantages

The injection molded plastic parts are suitable for various industrial applications in the new energy automobile industry, with customizable sizes and colors available. The company offers OEM/ODM services and holds various certifications.

Application Scenarios

The injection molded plastic parts are suitable for the new energy automobile industry, with spraying, electroplating, printing, and other surface treatments available. The company's well-trained workers ensure productivity and quality service for customers.

+86 13433648351