Best Injection Molding Companies with Custom Services

Product Overview

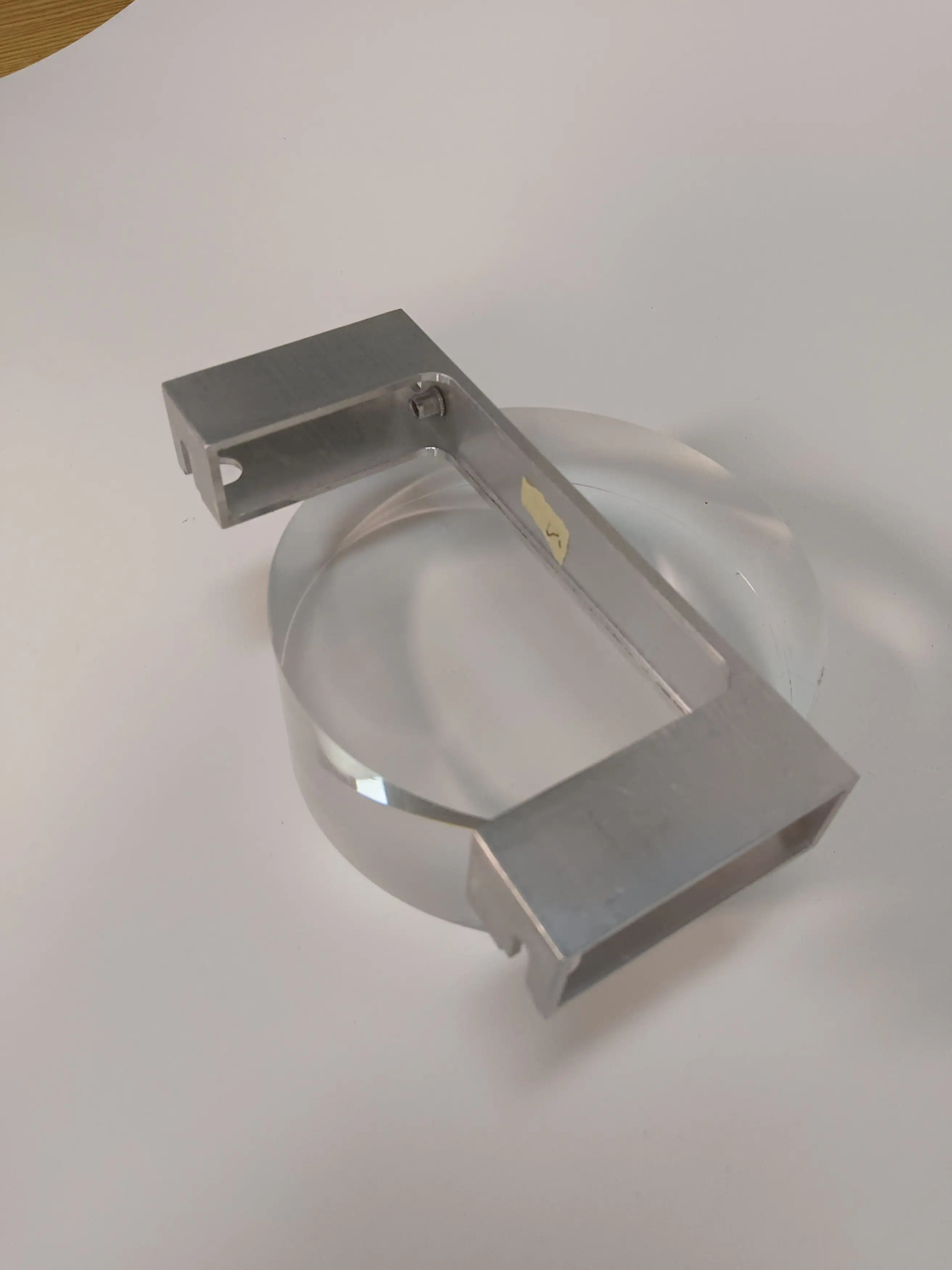

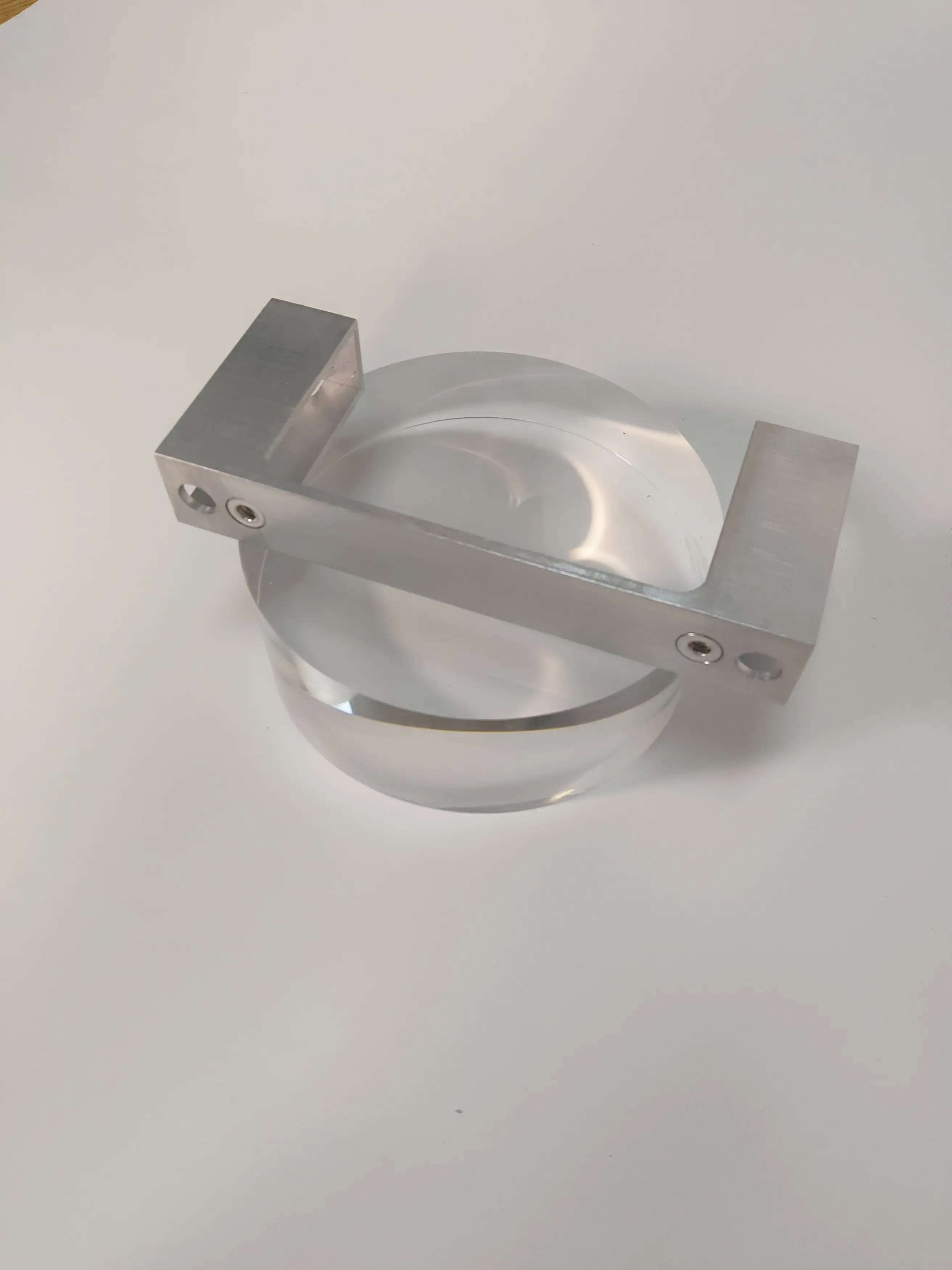

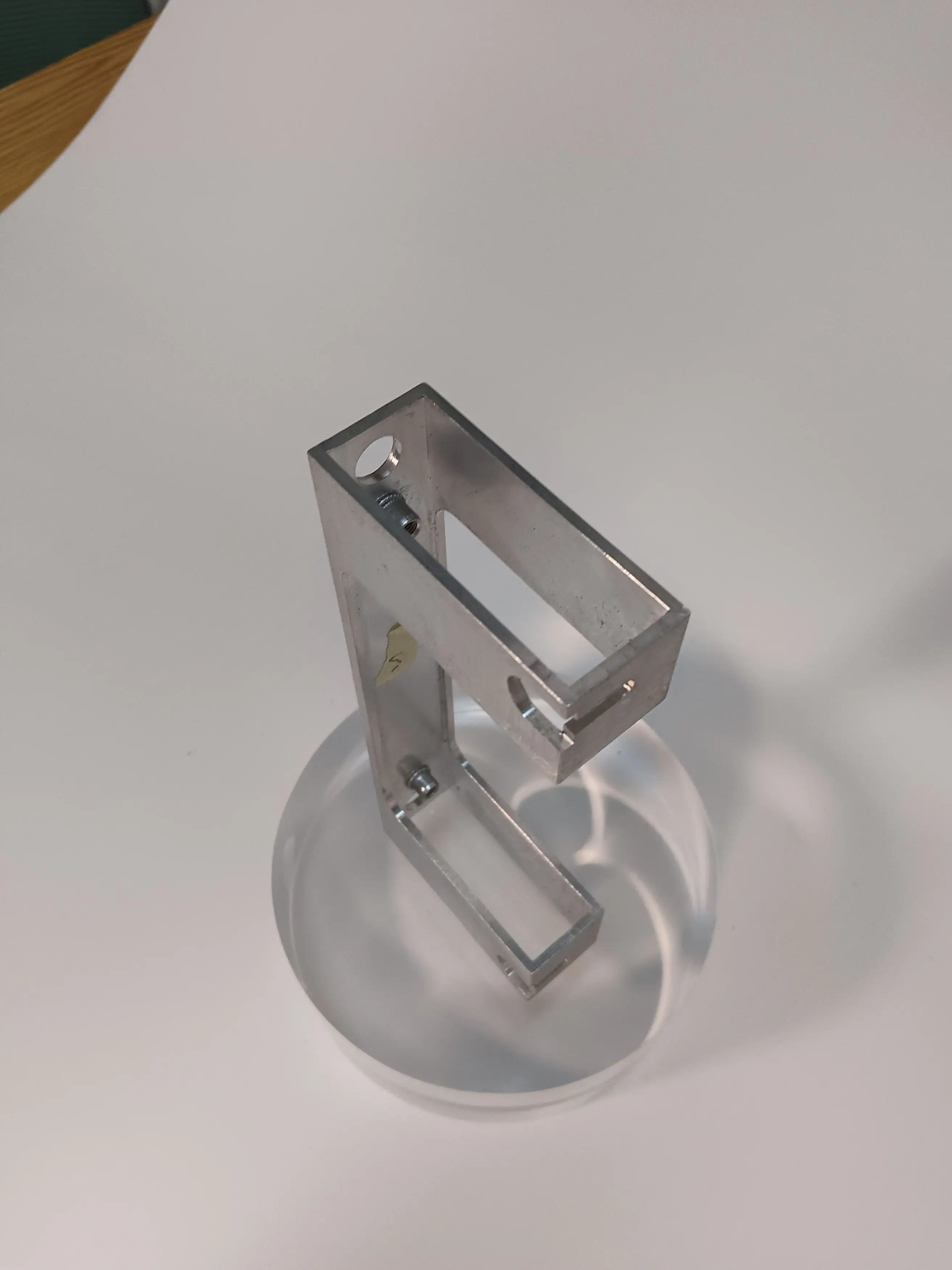

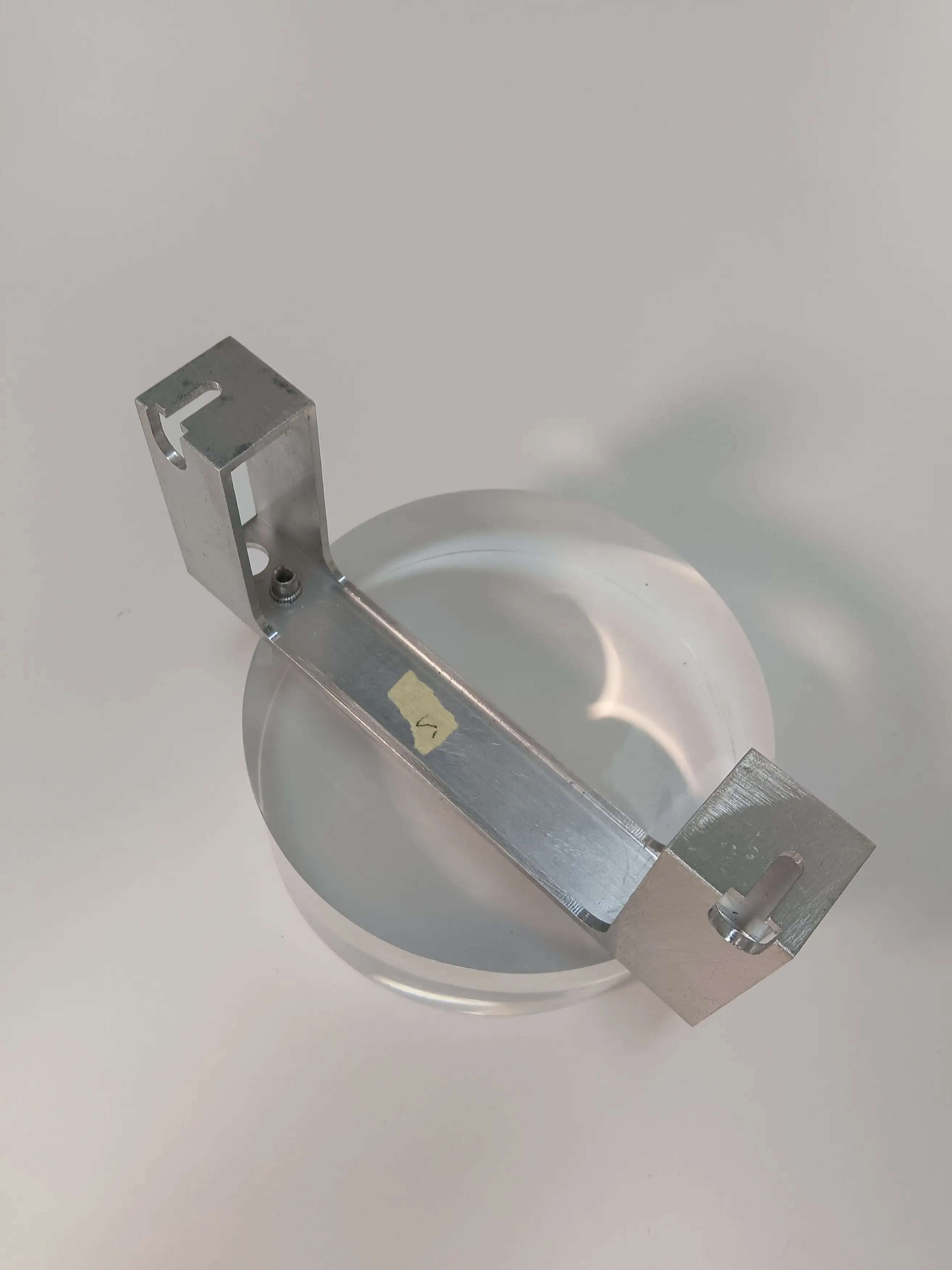

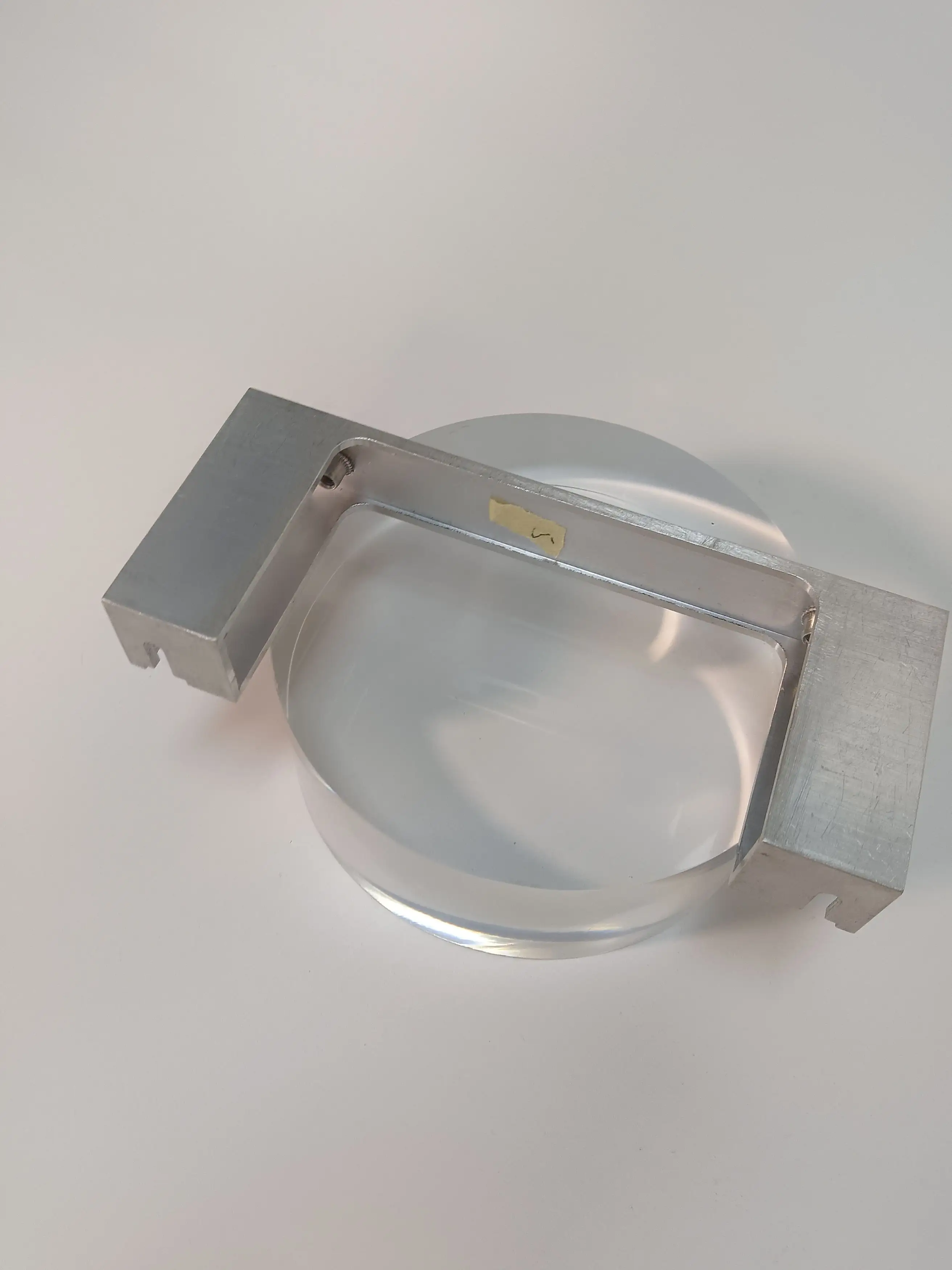

- The product is a bracket made of extruded aluminum using stamping, CNC machining, and nuts riveting.

- It requires polishing and deburring for a qualified appearance.

- Strict size control of concentric distance is ensured with the requirement of a FAI full size report for each batch of product.

- The bulk order production time is 20-25 days.

Product Features

- Made of materials such as copper, iron, aluminum, steel, stainless steel, tin, zinc.

- Surface treatments include plating, pad printing, screen printing, heat transfer.

- MOQ is 1 piece.

- Available in black/white and Pantone color numbers.

- Customizable size according to customer drawing file or sample.

Product Value

- High-quality materials ensure excellent mechanical and electrical properties.

- Precision injection molding process provides high dimensional accuracy and smooth surface.

- Focus on safety performance and durability for long-term use in harsh environments.

- Customized services available to meet specific customer requirements.

Product Advantages

- High-quality materials for excellent properties and stability.

- Precision process ensures high dimensional accuracy and smooth surface.

- Safety-focused design to prevent hazards and protect equipment and operators.

- Strong durability with resistance to corrosion, high temperature, and wear.

- Customized services for personalized requirements and strict quality control for stable product quality.

- Rapid response from professional sales and after-sales service team.

Application Scenarios

- Widely used in the automobile industry for various applications.

+86 13433648351