What is Metal Stamping and How Does It Work?

Metal Stamping and Its Process

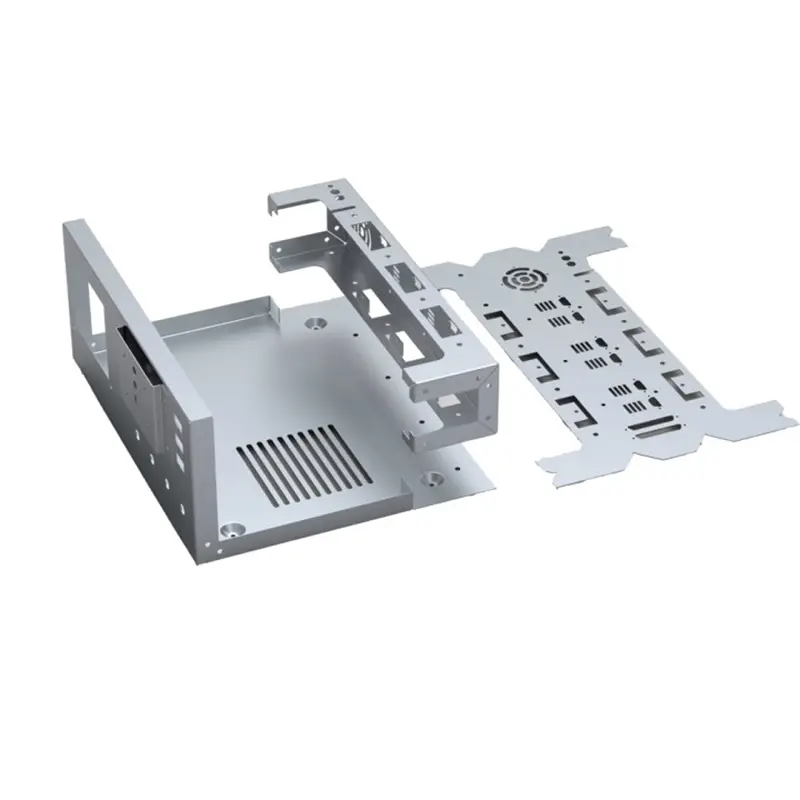

Metal stamping is a popular manufacturing process that involves shaping and forming metal sheets with the use of precision tooling and stamping dies. This process is commonly used in the production of a wide range of metal components and products that are used in various industries such as automotive, aerospace, electronics, and more. Metal stamping is known for its cost-effectiveness, high production output, and the ability to produce complex and intricate designs.

What is Metal Stamping?

Metal stamping, also known as pressing, is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Metal stamping includes a variety of sheet-metal forming manufacturing processes, such as punching, embossing, bending, flanging, and coining. These processes are carried out using stamping press machines and tool and die sets that are designed to apply sufficient force to shape and cut the metal sheet into the desired form.

Metal stamping can be categorized into two main types: progressive stamping and single-stage stamping. In progressive stamping, multiple operations are performed on the metal sheet as it moves through the tool and die set, resulting in the formation of the final part. Single-stage stamping, as the name suggests, only entails a single operation to produce the final part. Both types of stamping have their own advantages and are chosen based on the specific requirements of the part being manufactured.

Metal stamping is used to produce a wide variety of parts and products, ranging from simple washers and brackets to complex automotive components and intricate electronic enclosures. This process is known for its high precision and repeatability, making it a preferred choice for many manufacturers.

The Metal Stamping Process

The metal stamping process typically begins with the design of the part to be manufactured. Once the design is finalized, a tool and die set is created to form the metal sheet into the desired shape. The tool and die set consists of a male and female die that are used to apply the necessary force to the metal sheet. The metal sheet is fed into the stamping press, where it is placed between the male and female dies. The press then applies force to the metal sheet, causing it to be shaped and formed according to the contours of the dies.

The metal stamping process requires precise control over factors such as the force applied, the speed of operation, and the material being used. The choice of material is crucial in metal stamping, as it can affect the formability, strength, and appearance of the final part. Common materials used in metal stamping include steel, aluminum, copper, and stainless steel, among others.

Once the metal sheet has been formed into the desired shape, it undergoes additional operations such as trimming, piercing, and bending to achieve the final part. These secondary operations may be carried out in the same stamping press or in separate machines, depending on the complexity of the part being manufactured.

Advantages of Metal Stamping

Metal stamping offers several advantages that make it a preferred manufacturing process for many industries. One of the key advantages of metal stamping is its cost-effectiveness. Since the process can be automated and produces high volumes of parts in a short amount of time, it results in lower production costs. This makes metal stamping an ideal choice for mass production of parts and components.

Another advantage of metal stamping is its ability to produce complex and intricate designs with high precision and repeatability. This is important in industries such as automotive and aerospace, where parts must meet strict specifications and tolerances. Metal stamping also allows for the efficient use of material, as it minimizes waste and scrap during the production process.

Furthermore, metal stamping is a versatile process that can be used to manufacture a wide range of parts and products. Whether it's a simple bracket or a complex automotive component, metal stamping can effectively produce the desired part with the required specifications and quality.

Applications of Metal Stamping

Metal stamping is widely used in various industries and is an essential manufacturing process for the production of many components and products. In the automotive industry, metal stamping is used to produce body panels, brackets, suspension components, and other parts that are integral to the assembly of vehicles. The high precision and repeatability of metal stamping make it an ideal choice for automotive parts that require strict tolerances and specifications.

In the aerospace industry, metal stamping is used to manufacture parts for aircraft and spacecraft, including structural components, fittings, and brackets. The reliability and efficiency of metal stamping make it an important process in the production of aerospace components that must meet stringent quality and safety standards.

Metal stamping is also widely used in the electronics industry, where it is employed to produce enclosures, chassis, brackets, and other components for electronic devices and equipment. The ability to produce intricate designs and complex shapes makes metal stamping a suitable choice for the manufacturing of precision electronic components.

Challenges in Metal Stamping

While metal stamping offers many advantages, it also poses certain challenges that manufacturers must address. One of the key challenges in metal stamping is the complexity of tool and die design. The tool and die set must be carefully designed to ensure that the metal sheet is formed accurately and consistently, without defects or imperfections. This requires expertise in tool and die making, as well as a thorough understanding of material behavior and forming processes.

Another challenge in metal stamping is material selection. The choice of material can significantly impact the formability, strength, and overall performance of the final part. Manufacturers must carefully select the appropriate material for the specific application to ensure that the part meets the required specifications and quality standards.

In addition, maintaining tool and die performance is essential in metal stamping. The tool and die set undergoes constant wear and tear during the stamping process, and regular maintenance and replacement are necessary to ensure the quality and consistency of the formed parts. This adds to the overall production costs and requires careful planning and management of tool and die resources.

Summary

In conclusion, metal stamping is a widely used manufacturing process that offers cost-effectiveness, high production output, and the ability to produce complex and intricate designs. The process involves shaping and forming metal sheets using precision tooling and stamping dies, and it is used to manufacture a wide range of components and products for industries such as automotive, aerospace, and electronics. While metal stamping presents certain challenges such as tool and die design, material selection, and maintenance, the advantages of the process make it a preferred choice for many manufacturers. With its versatility, precision, and repeatability, metal stamping continues to be an essential process in the production of various metal parts and products.

+86 13433648351