What is injection molding? How does it work?

What is injection molding? How does it work?

Injection molding is a popular manufacturing process used to produce a wide range of plastic products. It is a cost-effective method that enables manufacturers to produce large quantities of identical plastic parts with high precision and consistency. In this article, we will explore how injection molding works and its various applications in different industries.

The Basics of Injection Molding

Injection molding involves the use of a mold or die to shape molten plastic material into a specific form. The process begins with the injection of the plastic material into the mold cavity, followed by the application of heat and pressure to solidify the material. Once the plastic part has cooled and solidified, it is ejected from the mold, and the process can be repeated to produce more parts.

The key components of an injection molding machine include the injection unit, clamping unit, and mold. The injection unit is responsible for melting and injecting the plastic material into the mold, while the clamping unit is used to hold the mold in place during the injection and cooling process. The mold, on the other hand, is designed to impart the desired shape and features to the plastic part.

Injection molding offers several advantages, including high production efficiency, minimal material waste, and the ability to produce complex and intricate shapes. It is widely used in the manufacturing of consumer products, automotive components, medical devices, and electronic parts, among others.

The Injection Molding Process

The injection molding process begins with the feeding of plastic pellets into the machine's hopper. The pellets are then heated and compressed into a molten state within the injection unit. Once the molten plastic reaches the desired temperature and viscosity, it is injected into the mold cavity under high pressure.

The injection stage is followed by a period of cooling, during which the molten plastic solidifies and takes on the shape of the mold. The cooling process is critical in ensuring that the plastic part retains its structural integrity and dimensional accuracy. Once the part has sufficiently cooled, the mold is opened, and the finished part is ejected from the machine.

Types of Injection Molding

There are several variations of the injection molding process, each tailored to meet specific manufacturing requirements. Some of the most common types of injection molding include:

- Conventional Injection Molding: This is the standard method of injection molding, where the plastic material is heated and injected into a closed mold to produce a single part at a time.

- Insert Molding: In this process, metal or plastic inserts are placed into the mold before the injection of the plastic material. This allows for the integration of multiple materials into a single part.

- Overmolding: Overmolding involves the use of multiple materials to create a single part with a soft-touch grip or a combination of rigid and flexible components.

- Micro Molding: Micro molding is used to produce extremely small and precise plastic parts, often with dimensions less than a millimeter.

- Multi-Shot Molding: This process enables the production of multi-material or multi-colored parts in a single molding cycle, resulting in cost savings and improved product functionality.

Each type of injection molding has its unique advantages and applications, making it suitable for a wide range of industries and product designs.

Materials Used in Injection Molding

A variety of thermoplastic and thermoset materials can be used in the injection molding process, each with its specific properties and applications. Some of the most commonly used injection molding materials include:

- Polyethylene (PE): PE is a versatile and cost-effective material used in the production of packaging, containers, and other consumer products.

- Polypropylene (PP): PP offers excellent chemical resistance and is commonly used in the manufacturing of automotive parts, appliances, and medical devices.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a tough and impact-resistant material used in the production of consumer electronics, automotive components, and toys.

- Polycarbonate (PC): PC is known for its high impact strength and optical clarity, making it suitable for applications such as lenses, electronic enclosures, and automotive lighting.

- Nylon: Nylon is a durable and abrasion-resistant material used in the production of gears, bearings, and other mechanical components.

In addition to these materials, there are many other thermoplastic and thermoset resins that can be used in injection molding, each offering unique properties to meet specific performance requirements.

Applications of Injection Molding

Injection molding is widely used in various industries to produce a diverse range of plastic products. Some common applications of injection molding include:

- Consumer Products: Injection molding is used to manufacture a wide range of consumer goods, including packaging, housewares, and children's toys.

- Automotive Components: Many interior and exterior automotive components, such as dashboards, bumpers, and trim panels, are produced using injection molding.

- Medical Devices: Injection molding is critical in the production of medical devices and equipment, including syringes, surgical instruments, and implantable devices.

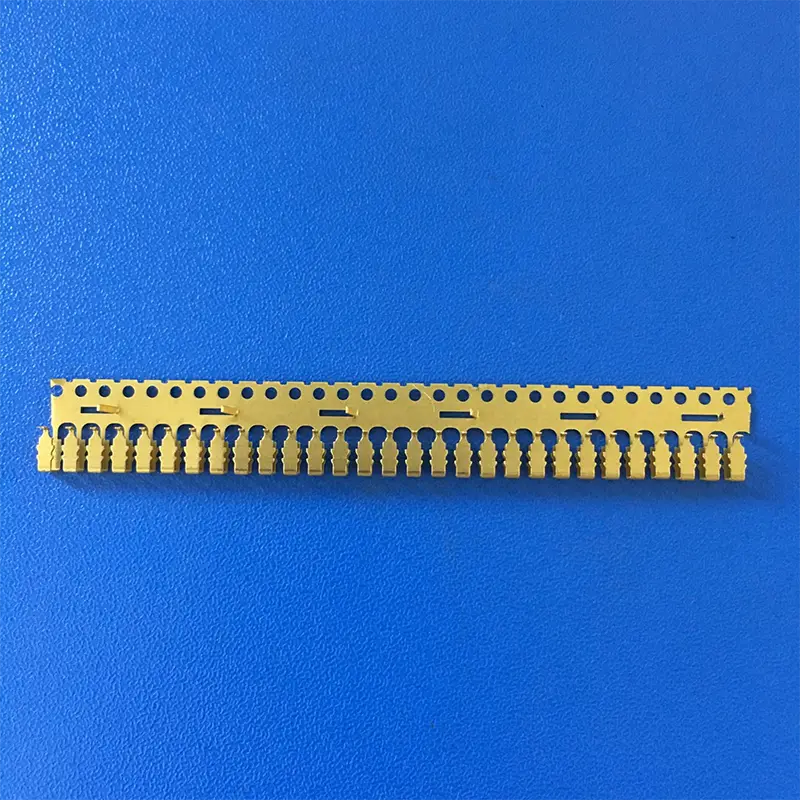

- Electronics: Plastic enclosures, connectors, and other electronic components are often manufactured using injection molding to meet the demands of the electronics industry.

- Industrial Components: Injection molding is used to produce a variety of industrial parts, such as gears, bearings, and custom components for machinery and equipment.

The versatility and efficiency of injection molding make it a preferred manufacturing method for a wide range of products across different industries.

Conclusion

Injection molding is a highly versatile and cost-effective manufacturing process that has revolutionized the production of plastic products. Its ability to produce large quantities of identical parts with high precision and consistency makes it a popular choice for industries ranging from consumer goods to automotive and medical devices. By understanding the basics of injection molding, its different variations, material options, and applications, manufacturers can leverage this process to create innovative and high-quality plastic products that meet the demands of today's market. With continuous advancements in technology and material science, the future of injection molding looks promising, with new opportunities for creating even more complex and functional plastic parts.

+86 13433648351