How to properly maintain and use precision stamping die

Precision stamping die is an essential tool used in the manufacturing industry to produce high-quality and precise metal components. To ensure the longevity and performance of precision stamping die, it is crucial to properly maintain and use it. In this article, we will discuss the best practices for maintaining and using precision stamping die to maximize its efficiency and productivity. From regular maintenance routines to proper usage techniques, we will cover everything you need to know to keep your precision stamping die in top condition.

Understanding Precision Stamping Die

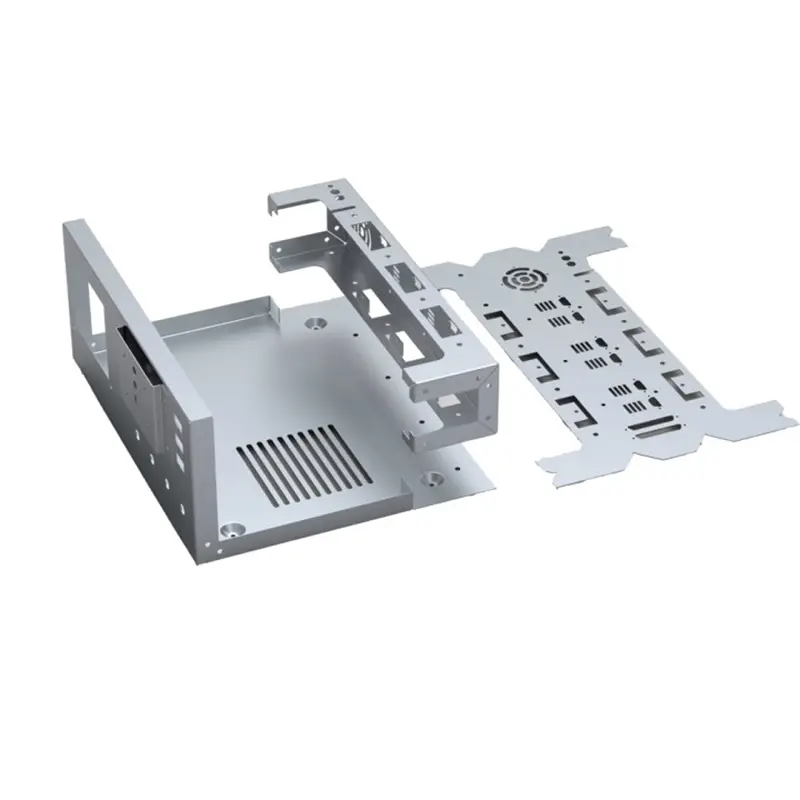

Precision stamping die, also known as metal stamping die, is a special tool used in the metalworking industry to shape and cut metal components with high precision and accuracy. It consists of a series of components, including punch, die, and blank holder, that work together to create intricate and complex metal parts. Precision stamping die is commonly used in industries such as automotive, aerospace, electronics, and medical devices to produce a wide range of metal parts, including brackets, contacts, clips, and connectors.

Proper understanding of precision stamping die is essential for its maintenance and usage. By familiarizing yourself with the different components and their functions, you can better appreciate the importance of proper maintenance and usage practices to ensure the quality and accuracy of the metal parts produced.

When it comes to maintaining and using precision stamping die, there are several key factors to consider. From regular inspection and lubrication to proper handling and storage, following these best practices can significantly extend the life of precision stamping die and optimize its performance.

Regular Inspection and Maintenance

Regular inspection and maintenance are essential for preserving the integrity and functionality of precision stamping die. By conducting routine checks and addressing any issues promptly, you can prevent potential problems and ensure consistent performance. During the inspection process, it is crucial to examine all components of the precision stamping die, including the punch, die, guide pins, and bushings, for signs of wear, damage, or misalignment. Any abnormalities should be addressed immediately to prevent further damage and maintain the precision and accuracy of the stamped parts.

In addition to visual inspection, regular maintenance tasks such as cleaning, lubrication, and tightening of components are necessary to keep the precision stamping die in optimal condition. Proper cleaning helps remove debris, dirt, and contaminants that can affect the tool's performance, while lubrication ensures smooth operation and reduces friction and wear. Tightening loose components and fasteners also prevents excessive movement and misalignment, which can compromise the quality of the stamped parts. By incorporating these maintenance routines into your operational schedule, you can prolong the life of precision stamping die and minimize the risk of downtime due to unexpected failures.

Proper Handling and Usage Techniques

Proper handling and usage techniques are equally important for maintaining the integrity and functionality of precision stamping die. Mishandling or misuse can lead to premature wear and damage, affecting the quality and accuracy of the stamped parts. When handling precision stamping die, it is important to use proper lifting equipment and techniques to prevent accidents and avoid unnecessary strain on the tool. Additionally, storing the precision stamping die in a clean and controlled environment, away from excessive heat, moisture, and contaminants, helps preserve its condition and performance.

Furthermore, using the precision stamping die within its design limits and recommended parameters is essential for ensuring consistent quality and accuracy of the stamped parts. Overloading the tool, using improper materials, or running at excessive speeds can cause undue stress and wear on the components, leading to reduced tool life and decreased precision. By adhering to the manufacturer's guidelines and specifications for material thickness, hardness, and press tonnage, you can optimize the performance and longevity of the precision stamping die.

Training and Education

Training and education are vital aspects of proper maintenance and usage of precision stamping die. Ensuring that operators and maintenance personnel are adequately trained and knowledgeable about the tool's operation, maintenance, and safety procedures is essential for maximizing its efficiency and longevity. Providing comprehensive training programs and resources on the proper handling, usage, and maintenance of precision stamping die can help prevent costly mistakes and ensure consistent quality and accuracy of the stamped parts.

In addition to initial training, ongoing education and refresher courses are essential for keeping operators and maintenance personnel up to date with the latest advancements and best practices in precision stamping die maintenance and usage. This continuous learning approach helps improve efficiency, productivity, and safety in the operation and maintenance of precision stamping die, ultimately leading to better overall performance and reduced downtime due to unexpected failures.

Implementing Preventive Maintenance Programs

Implementing preventive maintenance programs is crucial for the long-term performance and reliability of precision stamping die. By establishing a proactive maintenance schedule that includes regular inspections, cleaning, lubrication, and component replacement, you can address potential issues before they escalate into costly failures. Preventive maintenance programs help minimize downtime, extend tool life, and ensure consistent quality and accuracy of the stamped parts.

When developing a preventive maintenance program for precision stamping die, it is important to consider the tool's usage frequency, production volume, and environmental factors that may affect its performance. By tailoring the maintenance schedule to the specific operational conditions and demands, you can optimize the effectiveness of the program and maximize the longevity of the precision stamping die.

In summary, proper maintenance and usage of precision stamping die are essential for maximizing its efficiency and performance. By understanding the tool's components and functions, conducting regular inspection and maintenance, practicing proper handling and usage techniques, providing training and education, and implementing preventive maintenance programs, you can ensure the longevity and reliability of precision stamping die, ultimately leading to consistent quality and accuracy of the stamped parts. Incorporating these best practices into your operational and maintenance procedures can help minimize downtime, reduce costs, and improve overall productivity in the metal stamping process.

+86 13433648351