How to Make Injection Molds: The Complete Process from Start to Finish

Injecting molding is a crucial process in the manufacturing of various products. It involves creating a mold, injecting molten material, and then allowing it to cool and harden into the desired shape. If you're interested in learning how to make injection molds from start to finish, this article will provide you with a complete guide to the process.

Gathering Materials and Equipment

The first step in making injection molds is to gather all the necessary materials and equipment. You will need to acquire the mold base, mold material, injection molding machine, and any other tools and supplies required for the process. The mold base serves as the foundation for the mold, while the mold material will determine the properties and quality of the finished product. The injection molding machine is used to inject the molten material into the mold, so it is important to choose a machine that is suitable for the size and complexity of the mold you are creating. Additionally, you will need various tools such as clamps, cutting tools, and measuring devices to complete the mold-making process.

Once you have all the necessary materials and equipment, you can begin the process of making the injection mold.

Designing the Mold

The next step in making an injection mold is designing the mold itself. This involves creating a blueprint or computer-aided design (CAD) model of the mold that will be used to guide the manufacturing process. When designing the mold, it is important to consider factors such as the shape and size of the product, the material it will be made from, and any special features or requirements. The design should also take into account the capabilities of the injection molding machine and any potential issues that may arise during the injection process.

During the design phase, it is important to pay close attention to the details of the mold, as any mistakes or oversights in the design could result in a defective or substandard product. It may be necessary to consult with a mold design engineer or expert to ensure that the design is optimized for the injection molding process.

Creating the Mold Base

With the design of the mold finalized, the next step is to create the mold base. The mold base serves as the foundation for the mold, providing a stable and supportive structure for the mold cavity and other components. The mold base is typically made from steel or aluminum and is machined to the precise specifications of the mold design. This process involves cutting, drilling, and milling the mold base to create the necessary features and dimensions. The mold base will also include various components such as ejector pins, cooling channels, and alignment features that are essential for the proper functioning of the mold.

Once the mold base is complete, it must be thoroughly inspected and tested to ensure that it meets the required specifications and quality standards. Any issues or defects in the mold base must be addressed before proceeding to the next phase of the mold-making process.

Preparing the Mold Material

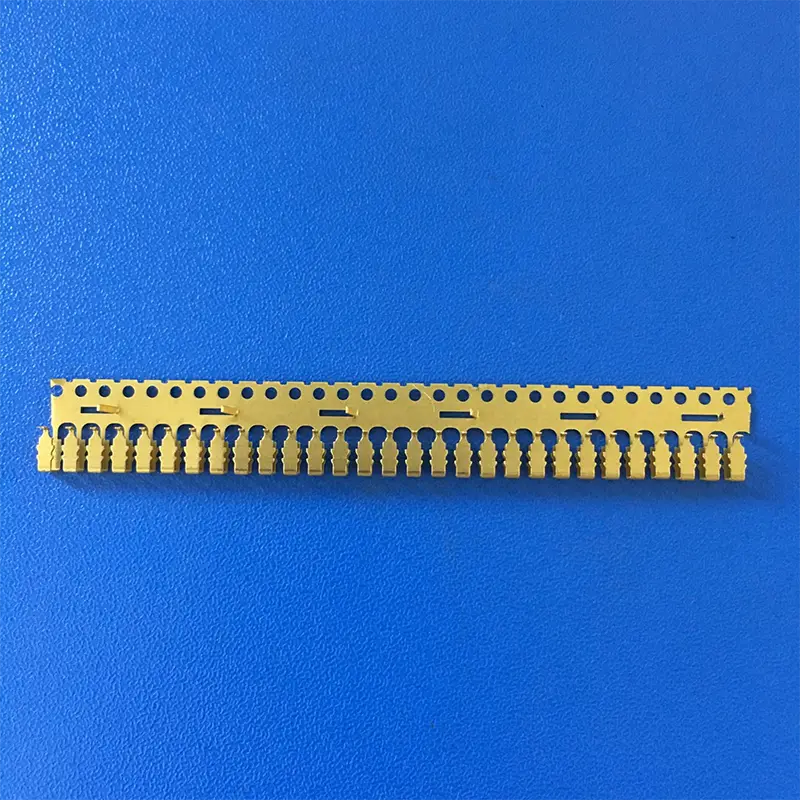

After the mold base has been created, the next step is to prepare the mold material. The mold material will determine the properties and characteristics of the finished product, so it is important to select a material that is appropriate for the intended use and performance requirements. Common materials used for injection molds include steel, aluminum, and various alloys, each of which has its own advantages and considerations.

The mold material must be carefully prepared and processed to ensure that it is suitable for the injection molding process. This may involve cutting, milling, and shaping the material to create the mold cavity and other features. It is important to pay close attention to the details of the mold material, as any imperfections or errors in the material preparation could result in defects or failures in the finished product.

Assembling the Mold Components

Once the mold base and material are ready, the next step is to assemble the various components of the mold. This involves fitting the mold material into the mold base and securing it in place using clamps or other fastening devices. It also involves installing any additional components such as ejector pins, cooling channels, and alignment features that are essential for the proper operation of the mold.

During the assembly process, it is important to ensure that all components are properly aligned and fitted to prevent any issues or problems during the injection molding process. It may be necessary to conduct trial runs or test molds to verify that the mold components are functioning as intended.

In conclusion, making injection molds is a complex and detailed process that requires careful planning, design, and execution. By following the steps outlined in this article, you can learn how to make injection molds from start to finish and produce high-quality products that meet your specific requirements. Whether you are a beginner or an experienced professional, the information provided here will help you understand the key principles and considerations involved in the mold-making process. By mastering the art of injection molding, you can take your manufacturing capabilities to the next level and create innovative and impactful products that meet the needs of your customers and clients.

+86 13433648351