How to Maintain Precision in High-Volume Metal Stamping?

Metal stamping is a popular method for creating high-volume, precision metal components. From automotive parts to appliances to electronics, metal stamping is used across various industries to produce large quantities of consistent, high-quality parts. However, maintaining precision in high-volume metal stamping can be challenging due to the complex nature of the process. In this article, we will explore how to maintain precision in high-volume metal stamping, including the importance of tooling, material selection, process control, and quality assurance.

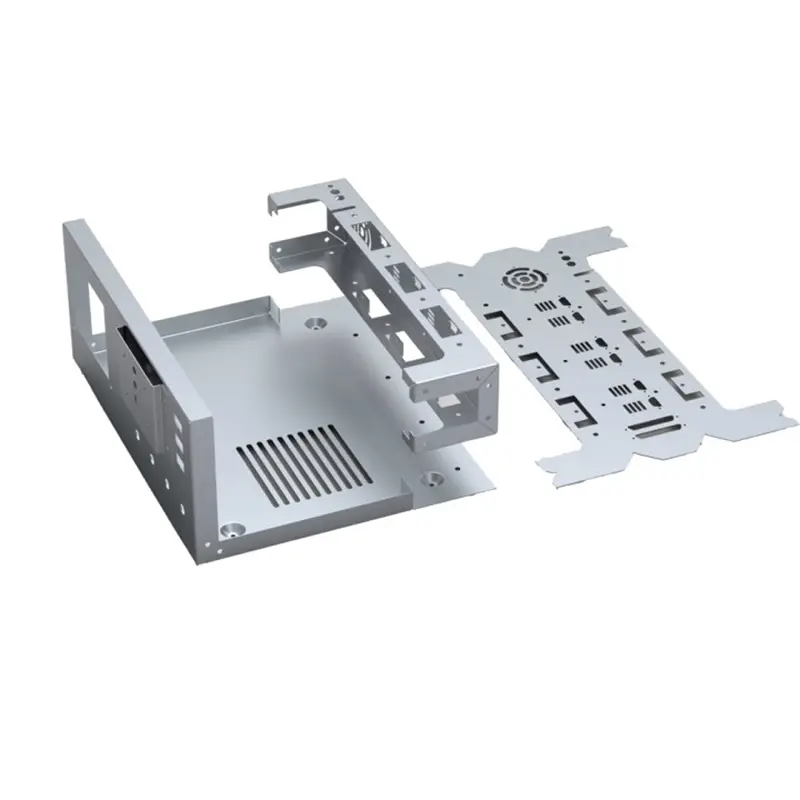

Importance of Tooling in Metal Stamping

Tools are critical components in the metal stamping process, as they are responsible for shaping and cutting the metal into the desired form. The quality and precision of the tools directly impact the accuracy and consistency of the stamped parts. High-volume metal stamping requires durable and high-precision tooling that can withstand the demands of continuous production.

To maintain precision in high-volume metal stamping, it is essential to invest in high-quality tooling materials, such as hardened steel, carbide, or tool steel. These materials offer superior wear resistance and dimensional stability, ensuring that the tools maintain their precision over extended production runs. Additionally, regular maintenance and sharpening of the tools are necessary to prevent wear and maintain their cutting edges.

Proper tool design is also crucial for precision in high-volume metal stamping. The tooling must be engineered to minimize deflection and vibration during the stamping process, as these factors can lead to dimensional inaccuracies in the finished parts. By optimizing the tool design, manufacturers can achieve tighter tolerances and consistent part dimensions, even during high-volume production runs.

Material Selection for Precision Metal Stamping

The selection of materials is another crucial factor in maintaining precision in high-volume metal stamping. The choice of metal affects the formability, strength, and dimensional stability of the stamped parts. For high-volume production, it is essential to select materials that offer consistent mechanical properties and dimensional accuracy.

One key consideration is the uniformity of material properties across production batches. Variations in material composition or microstructure can lead to inconsistencies in the stamped parts, compromising precision. To mitigate this risk, manufacturers should work closely with material suppliers to ensure strict material specifications and quality control measures.

In addition to material consistency, the selection of the appropriate metal grade is essential for precision in high-volume metal stamping. Some metals, such as stainless steel or aluminum, offer better formability and dimensional stability, making them ideal for high-volume stamping applications. Furthermore, the material's surface finish and cleanliness play a critical role in achieving precision, as any imperfections or contaminants can affect the stamping process and the final part quality.

Process Control in High-Volume Metal Stamping

Process control is essential for maintaining precision in high-volume metal stamping. The stamping process involves various parameters, such as press speed, die clearance, lubrication, and material feed, all of which can impact the dimensional accuracy and quality of the stamped parts. To ensure consistency and precision, it is crucial to implement robust process control measures.

One important aspect of process control is the optimization of the stamping parameters. By carefully adjusting parameters such as press force, speed, and dwell time, manufacturers can achieve better control over the stamping process and minimize dimensional variations. Advanced press control systems, such as servo-driven presses, offer precise control over the stamping process, allowing for tighter tolerances and improved part quality.

Furthermore, die maintenance and inspection are essential for process control in high-volume metal stamping. Worn or damaged dies can lead to dimensional inaccuracies and part defects, affecting the overall precision of the stamped parts. Regular die maintenance and inspection help identify and address potential issues before they impact part quality. In addition, implementing in-line quality control measures, such as vision inspection systems or laser measurement devices, can further enhance process control and ensure the precision of the stamped parts.

Quality Assurance in High-Volume Metal Stamping

Quality assurance is a critical component of maintaining precision in high-volume metal stamping. By implementing robust quality control measures, manufacturers can ensure that the stamped parts meet the required dimensional tolerances and quality standards. Quality assurance starts with comprehensive process documentation, including detailed specifications for part dimensions, material requirements, and inspection criteria.

In-process inspection is an essential aspect of quality assurance in high-volume metal stamping. By performing regular dimensional checks and visual inspections during production runs, manufacturers can identify any deviations from the specifications and take corrective actions to maintain precision. In addition, implementing statistical process control (SPC) techniques allows manufacturers to monitor key process parameters and detect any trends or variations that could affect part quality.

Furthermore, post-stamping inspection is crucial for quality assurance in high-volume metal stamping. This may involve dimensional metrology, surface finish evaluation, and material testing to verify the precision and quality of the stamped parts. Advanced inspection technologies, such as coordinate measuring machines (CMMs) and optical profilometers, offer high-precision measurement capabilities for assessing part dimensions and geometric tolerances.

Conclusion

In conclusion, maintaining precision in high-volume metal stamping is essential for producing consistent and high-quality parts across large production runs. By focusing on critical factors such as tooling, material selection, process control, and quality assurance, manufacturers can achieve the precision required for demanding applications. Investing in high-quality tooling, selecting the right materials, optimizing the stamping process, and implementing robust quality control measures are all essential for ensuring the accuracy and consistency of stamped parts in high-volume production. By addressing these key considerations, manufacturers can meet the stringent requirements of precision metal stamping and deliver reliable, high-quality components to their customers.

+86 13433648351