How to create custom metal molds

Metal molds are an essential tool in the manufacturing and fabrication industry. They are used to create a wide range of products, from automotive parts to household appliances. While there are many pre-made metal molds available on the market, there may be times when a custom mold is necessary. Creating custom metal molds allows for greater flexibility and customization in the manufacturing process. In this article, we will explore the process of creating custom metal molds, including the materials needed, the steps involved, and the benefits of using custom molds.

Understanding the Basics of Metal Molds

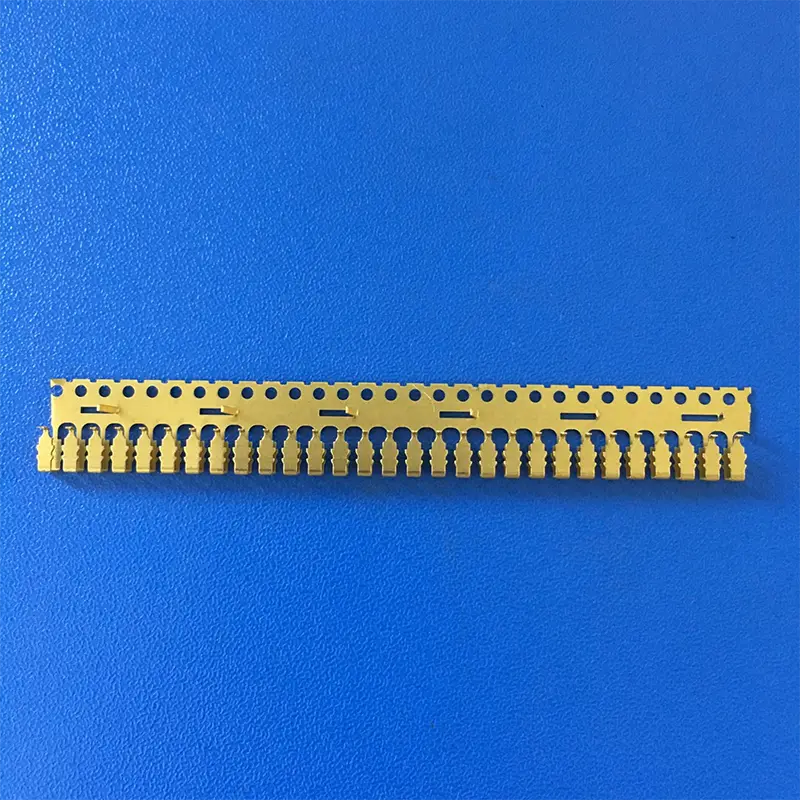

Before diving into the process of creating custom metal molds, it is important to have a basic understanding of what metal molds are and how they are used. Metal molds are typically made from materials such as steel, aluminum, or copper. These materials are chosen for their durability and ability to withstand high temperatures and pressure. Metal molds are used in various manufacturing processes, including injection molding, die casting, and stamping. They are designed to shape and form raw materials into a specific shape or size, allowing for the mass production of consistent and high-quality products.

To create a custom metal mold, it is essential to have a clear understanding of the product or part that will be produced. This includes detailed specifications such as dimensions, material type, and any specific design features. Once these specifications are known, the process of creating a custom metal mold can begin.

Choosing the Right Materials

The first step in creating a custom metal mold is to choose the right materials. The type of material used will depend on the specific requirements of the product or part being manufactured. Steel is a popular choice for metal molds due to its strength and durability. It can withstand high temperatures and pressure, making it suitable for a wide range of manufacturing processes. Aluminum is another common material used for metal molds. It is lightweight and has good thermal conductivity, making it ideal for molds that require rapid cooling. Copper is also used for metal molds, especially in applications where heat transfer is a critical factor.

When choosing the right material for a custom metal mold, it is important to consider the specific requirements of the manufacturing process. Factors such as temperature resistance, wear resistance, and surface finish will all play a role in determining the best material for the job. Consulting with a materials engineer or a metalworking specialist can help ensure that the right material is chosen for the custom mold.

Designing the Mold

Once the material for the custom metal mold has been chosen, the next step is to design the mold. This involves creating a detailed blueprint or 3D model of the mold that will be used to manufacture the product. The design process will take into account the specific requirements of the product, including dimensional tolerances, surface finish, and any complex features or details.

There are a variety of software tools available for designing custom metal molds, including computer-aided design (CAD) software and computer-aided manufacturing (CAM) software. These tools allow for precise and accurate design, as well as the simulation of the manufacturing process to identify any potential issues or challenges. The design phase also involves considering factors such as cooling channels, ejection systems, and parting lines, all of which are critical to the success of the custom metal mold.

When designing a custom metal mold, it is important to work closely with a design engineer or a mold specialist who has experience in creating molds for the specific manufacturing process. Their expertise can help ensure that the mold is designed to meet the necessary specifications and requirements.

Manufacturing the Mold

Once the design of the custom metal mold has been finalized, the next step is to manufacture the mold. This involves using a variety of metalworking processes, including milling, turning, and grinding, to create the mold from the chosen material. CNC machining is often used to manufacture custom metal molds, as it allows for precise and accurate production of complex shapes and features.

During the manufacturing process, it is important to pay close attention to the dimensional accuracy and surface finish of the mold. Any errors or imperfections in the mold can result in defects in the final product, leading to increased scrap rates and production costs. Quality control measures such as inspection and testing should be implemented throughout the manufacturing process to ensure that the custom metal mold meets the necessary specifications and requirements.

In some cases, additional processes such as heat treatment or surface coating may be required to enhance the performance and longevity of the custom metal mold. These processes can help improve the wear resistance, corrosion resistance, and overall durability of the mold, ensuring that it can withstand the demands of the manufacturing process.

Benefits of Using Custom Metal Molds

There are several benefits to using custom metal molds in the manufacturing process. One of the primary benefits is the ability to create complex and intricate parts or products that may not be possible with standard off-the-shelf molds. Custom molds allow for greater flexibility and customization, allowing manufacturers to create unique and innovative products that set them apart from the competition.

Custom metal molds also allow for greater control over the manufacturing process, resulting in higher quality products and reduced scrap rates. By customizing the mold to meet specific requirements, manufacturers can optimize the production process, resulting in improved efficiency and cost savings. Additionally, custom metal molds can help reduce lead times and time-to-market, allowing for faster production of new products or parts.

In summary, creating custom metal molds is an essential process in the manufacturing and fabrication industry. By understanding the basics of metal molds, choosing the right materials, designing the mold, manufacturing the mold, and understanding the benefits of using custom molds, manufacturers can leverage the power of custom molds to create high-quality products and gain a competitive edge in the market. The ability to produce custom metal molds opens up new possibilities for manufacturers to explore and innovate, leading to a more efficient and successful manufacturing process.

+86 13433648351