How to Accurately Judge the Precision of press mold

Understanding the Importance of Precision in Press Mold

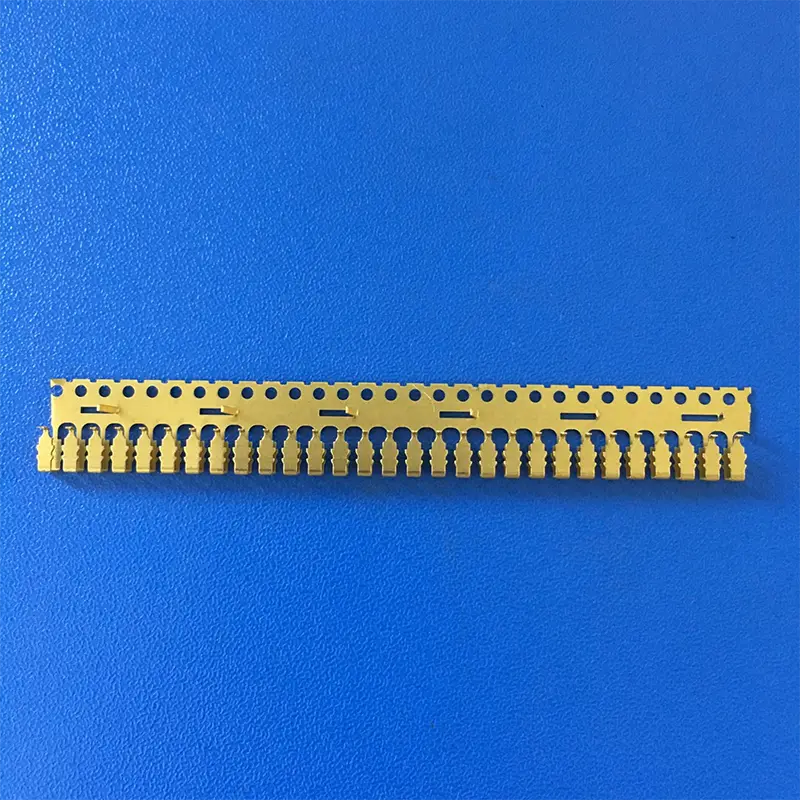

Precision in press mold is critical for ensuring the quality and accuracy of the final product. Whether you are working with plastic, metal, or any other material, the precision of the press mold will directly impact the quality and performance of the finished product. In this article, we will discuss how to accurately judge the precision of press mold and why it is essential for the manufacturing process.

Factors Affecting Precision in Press Mold

Several factors can affect the precision of press mold, including the quality of the mold material, the design of the mold, the manufacturing process, and the skill of the operator. Each of these factors plays a crucial role in determining the overall precision of the press mold and, ultimately, the quality of the finished product.

The quality of the mold material is essential for achieving high precision in press mold. Using high-quality materials that are resistant to wear and deformation is crucial for maintaining the accuracy and integrity of the mold over time. Additionally, the design of the mold, including factors such as tolerance, clearance, and surface finish, will also impact its precision.

The manufacturing process used to create the mold can also affect its precision. Processes such as CNC machining and EDM (electrical discharge machining) can produce highly precise molds, while other methods may result in lower precision. Lastly, the skill and experience of the operator are critical for ensuring that the mold is used correctly and maintained properly to achieve the desired level of precision.

Measuring Precision in Press Mold

Accurately measuring the precision of press mold is essential for maintaining quality control and ensuring that the finished products meet the required specifications. There are several methods for measuring precision in press mold, including dimensional inspection, surface finish measurement, and geometric dimensioning and tolerancing (GD&T).

Dimensional inspection involves measuring the physical dimensions of the mold to ensure that it meets the specified requirements. This can be done using tools such as calipers, micrometers, and coordinate measuring machines (CMMs). Surface finish measurement is used to assess the quality of the mold's surface, which is important for achieving the desired surface finish on the finished product. GD&T is a system for defining and communicating engineering tolerances and is commonly used to assess the precision of press mold.

When measuring precision in press mold, it is essential to consider both the individual components of the mold and the overall assembly. This comprehensive approach will ensure that all aspects of the mold are accurately assessed, and any issues can be identified and addressed.

Evaluating the Impact of Precision on Product Quality

The precision of the press mold directly impacts the quality of the finished product in several ways. Firstly, a precise mold will produce parts that meet the required specifications, including dimensional accuracy and surface finish. This is important for ensuring that the parts function correctly and meet the aesthetic requirements of the end-user.

In addition to dimensional accuracy and surface finish, the precision of the press mold also affects the overall performance and longevity of the finished product. For example, in industries such as automotive and aerospace, where parts are subject to high stress and extreme conditions, precision is crucial for ensuring the reliability and safety of the final product.

Furthermore, the precision of the press mold can impact the efficiency of the manufacturing process. A precise mold will produce parts that require minimal rework or adjustment, reducing scrap and increasing overall productivity. This is particularly important in high-volume production environments, where small improvements in precision can have a significant impact on the bottom line.

Methods for Improving Precision in Press Mold

There are several methods for improving the precision of press mold, ranging from the selection of high-quality materials to the implementation of advanced manufacturing techniques. By focusing on these key areas, manufacturers can enhance the precision of their press molds and, in turn, improve the quality and performance of their finished products.

The first step in improving precision in press mold is to use high-quality mold materials that are resistant to wear and deformation. Materials such as tool steel and high-performance alloys are commonly used for their durability and reliability. Additionally, advanced surface treatments and coatings can further enhance the precision and longevity of the mold.

In terms of the mold design, leveraging advanced CAD/CAM software and simulation tools can help optimize the design for precision and performance. These tools allow manufacturers to analyze the behavior of the mold under various operating conditions and make informed design decisions to improve precision.

Advanced manufacturing techniques, such as CNC machining and EDM, can also be used to improve the precision of press mold. These methods offer high levels of accuracy and repeatability, allowing for the production of complex and intricate mold designs with tight tolerances.

Summary

In conclusion, the precision of press mold is a critical factor in the manufacturing process, directly impacting the quality, performance, and efficiency of the finished product. By understanding the factors that affect precision, measuring and evaluating precision, and implementing methods to improve precision, manufacturers can ensure that their press molds meet the required specifications and deliver high-quality products to their customers. With the increasing demands for precision in various industries, the ability to accurately judge the precision of press mold is more important than ever.

+86 13433648351