How Kasem Delivers Consistent Excellence in Mold Making

Advanced Techniques in Mold Making

Kasem is a leading company in the manufacturing industry, known for its consistent excellence in mold making. With advanced techniques and state-of-the-art technology, Kasem delivers high-quality molds that exceed customer expectations. In this article, we will delve into how Kasem achieves consistent excellence in mold making, the techniques they use, and the impact their products have on the industry.

Meticulous Design Process

The first step in achieving consistent excellence in mold making is a meticulous design process. Kasem employs a team of experienced engineers and designers who work closely with clients to understand their specific requirements. They use advanced software and 3D modeling to create highly detailed designs that meet the exact specifications of the client. The ability to customize molds to the client's needs sets Kasem apart in the industry, leading to a high level of customer satisfaction.

Kasem's meticulous design process also includes thorough analysis and simulation to ensure the functionality of the mold. This helps identify any potential issues early in the process, minimizing the need for rework and ensuring a smooth production cycle. By paying attention to every detail in the design phase, Kasem sets the foundation for excellence in mold making.

Precision Machining

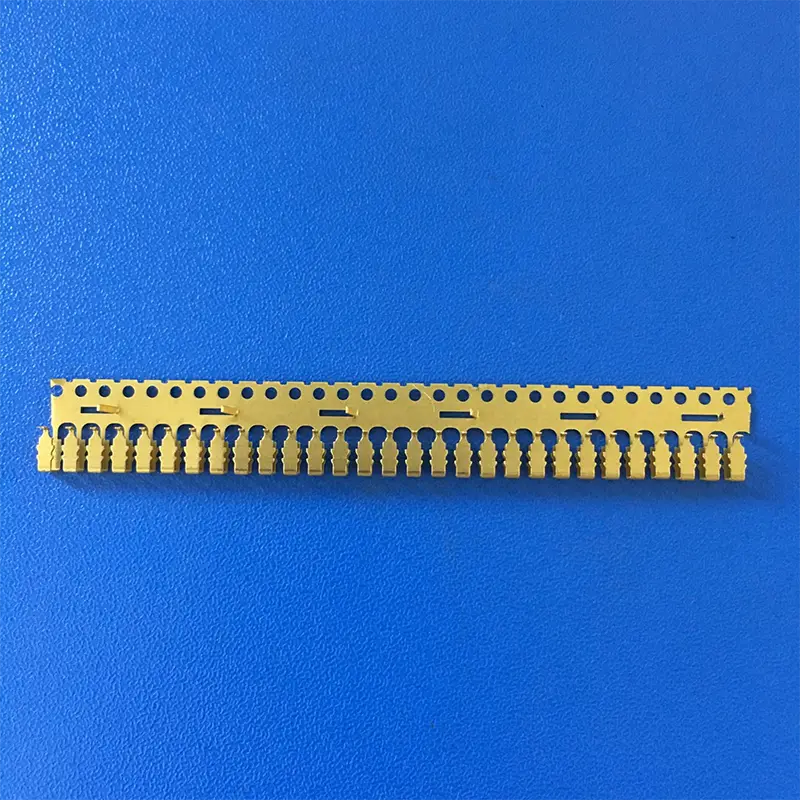

Once the design is finalized, Kasem's precision machining comes into play. The company invests in the latest CNC machines and other cutting-edge equipment to accurately produce molds with tight tolerances. Their skilled machinists meticulously follow the design specifications to ensure that every component of the mold is precisely machined to perfection.

Furthermore, Kasem's commitment to precision goes beyond just the end product. They have stringent quality control measures in place at every stage of the machining process, ensuring that each mold meets the highest standards of quality. This dedication to precision machining is a key factor in Kasem's ability to consistently deliver excellence in mold making.

Quality Materials and Expert Craftsmanship

Another aspect that sets Kasem apart in mold making is their use of high-quality materials and expert craftsmanship. The company sources the finest materials for mold production, carefully selecting alloys and tool steels that are known for their durability and longevity. Combined with the skills of their expert craftsmen, Kasem produces molds that can withstand the rigors of high-volume production.

The craftsmanship at Kasem is second to none, with skilled artisans using advanced techniques to create intricate molds with complex geometries. Whether it's injection molds, blow molds, or compression molds, Kasem's team has the expertise to produce top-quality results. This combination of quality materials and expert craftsmanship is a testament to Kasem's commitment to delivering excellence in mold making.

Innovation and Continuous Improvement

Kasem stays ahead of the curve in mold making through innovation and a focus on continuous improvement. The company invests in research and development, exploring new technologies and techniques to enhance their mold making capabilities. This proactive approach allows them to offer cutting-edge solutions to their clients, meeting the evolving needs of the industry.

Furthermore, Kasem encourages a culture of continuous improvement within their organization. They welcome feedback from clients and employees, using it to drive innovation and make incremental advancements in their processes. This commitment to staying at the forefront of mold making ensures that Kasem maintains its reputation for consistent excellence in the industry.

Exceptional Customer Service and Support

One of the key factors contributing to Kasem's consistent excellence in mold making is their exceptional customer service and support. From the initial consultation to the delivery of the final product, Kasem's team provides personalized attention to each client, ensuring that their needs are met and their expectations exceeded. This level of dedication to customer service sets Kasem apart as a trusted partner in the industry.

Kasem's support extends beyond just the delivery of the mold. They offer assistance with installation, troubleshooting, and ongoing maintenance, making sure that their clients get the most out of their investment. This comprehensive approach to customer service reinforces the company's commitment to excellence and solidifies their position as a leader in mold making.

In conclusion, Kasem's consistent excellence in mold making is the result of a combination of factors, including advanced techniques, meticulous design processes, precision machining, quality materials, expert craftsmanship, innovation and continuous improvement, and exceptional customer service and support. By prioritizing these aspects, Kasem has earned a reputation for delivering top-quality molds that meet the needs of a diverse range of industries. As the manufacturing landscape continues to evolve, Kasem remains at the forefront, poised to continue setting the standard for excellence in mold making.

+86 13433648351