How Injection Molds Work: Step-by-Step Guide for Injection Molds Manufacturer-1

Injecting molding is a widely used manufacturing process that involves the use of an injection molding machine, raw material, and a mold to produce a wide range of products. The process is highly efficient and cost-effective, making it one of the go-to methods for mass production of plastic products. In this comprehensive guide, we will take a detailed look at how injection molds work, focusing on each step involved in the process. Whether you are new to injection mold manufacturing or looking to gain more insight into the process, this guide will provide you with all the essential information you need.

Understanding Injection Molds

Before delving into the step-by-step process of how injection molds work, it is crucial to have a good understanding of what injection molds are. Injection molds are custom-made tools used in the injection molding process to produce plastic products and parts in large volumes. These molds are typically made from steel or aluminum and are precision-machined to form the desired shape of the product. Injection molds come in various designs and sizes, depending on the complexity and size of the product being manufactured.

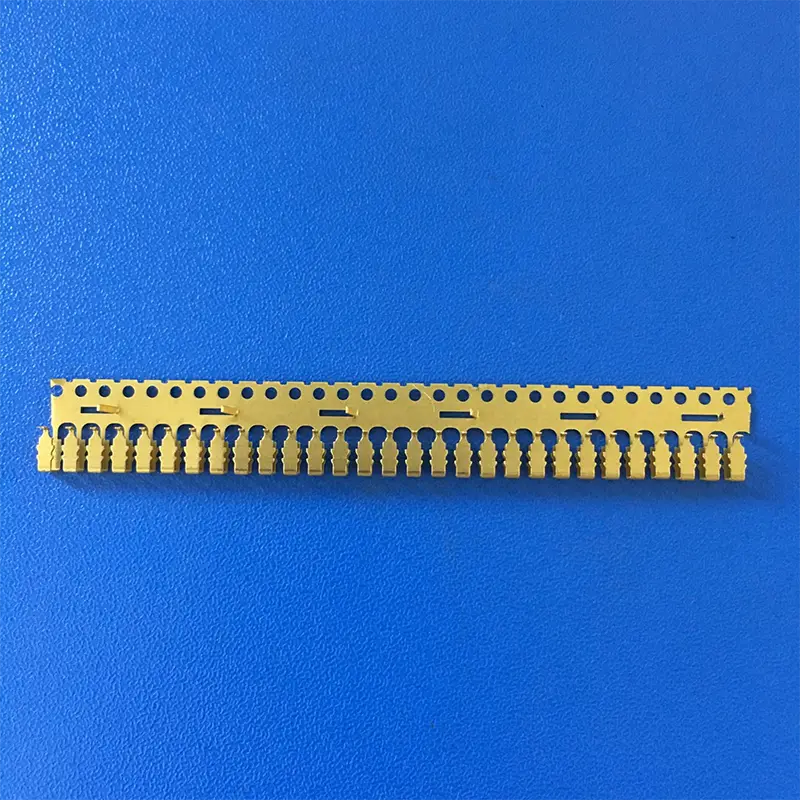

Injection molds consist of two main parts - the mold base and the mold cavity. The mold base provides the support for the mold cavity and other components, while the mold cavity is used to shape the raw material into the desired product. Additionally, injection molds can also include features such as cooling channels, ejector pins, and slides to facilitate the production process. Overall, injection molds play a critical role in the injection molding process and directly influence the quality and consistency of the final product.

The Injection Molding Process

The injection molding process can be broken down into several key steps, each of which plays a crucial role in the overall production process. Understanding each of these steps is essential for any injection molds manufacturer to ensure the successful and efficient manufacturing of plastic products. Let's take a closer look at each step involved in the injection molding process.

Step 1: Clamping

The first step in the injection molding process is clamping, which involves securing the mold in the injection molding machine. The mold is firmly clamped to the machine to prevent any movement during the injection and cooling phases. The clamping force applied to the mold is significant and is determined by factors such as the size and complexity of the mold and the type of material being used. Proper clamping is essential to prevent any potential issues such as flash, warping, or product defects during the injection molding process.

Once the mold is securely clamped, the injection molding machine's heating and injection units can then begin their respective processes. Clamping is a critical step in ensuring the success of the injection molding process and requires precision and accuracy to achieve the desired results.

Step 2: Injection

The injection step involves the introduction of the raw material into the mold cavity. The raw material, typically in the form of plastic pellets or granules, is fed into the hopper of the injection molding machine. The material is then heated and melted in the machine's heating barrel before being injected into the mold cavity under high pressure. This high-pressure injection ensures that the mold cavity is fully filled and that the material is evenly distributed throughout the cavity.

The injection phase is a crucial step in the process, as it directly impacts the quality and integrity of the final product. Proper control of the injection speed, pressure, and temperature is essential to achieve the desired results and prevent any potential issues such as sink marks, voids, or flow lines in the finished product.

Step 3: Cooling

Once the mold cavity is filled with the molten material, the cooling phase begins. During this phase, the material in the mold cavity begins to solidify and take on the shape of the product. The cooling process is typically achieved through the use of cooling channels within the mold, which help to regulate the temperature and speed up the solidification of the material.

Proper cooling is essential to ensure that the product retains its shape and form without any deformities or shrinkage. The cooling time and temperature are carefully monitored and controlled to achieve the desired results. Once the material has sufficiently cooled and solidified, the mold can be opened, and the finished product can be ejected from the mold cavity.

Step 4: Ejection

The ejection step involves the removal of the finished product from the mold cavity. After the cooling phase is complete, the mold is opened, and the ejection mechanism within the mold is activated to push the finished product out of the cavity. Ejector pins, plates, or slides are commonly used to facilitate the ejection process and ensure the smooth removal of the product from the mold.

Proper ejection is essential to prevent any damage to the finished product or the mold itself. Care should be taken to ensure that the product is fully ejected from the mold cavity without any sticking or deformation. Once the product has been ejected, the mold can be closed, and the next cycle of the injection molding process can begin.

Step 5: Inspection and Packaging

The final step in the injection molding process involves inspecting the finished products and packaging them for distribution. The finished products are carefully inspected for any defects, imperfections, or inconsistencies to ensure that they meet the required quality standards. Any defective or substandard products are removed from the production line to prevent them from reaching the market.

Once the products have been inspected and approved, they are packaged according to the customer's requirements and prepared for distribution. Proper packaging is essential to protect the products during shipping and storage and to present them in an attractive and professional manner to the end consumer.

In conclusion, the injection molding process is a highly efficient and effective method for the mass production of plastic products. Understanding how injection molds work and the various steps involved in the process is crucial for any injection molds manufacturer to ensure the successful and consistent production of high-quality products. By following best practices and closely monitoring each step of the injection molding process, manufacturers can achieve optimal results and meet the demands of their customers.

+86 13433648351