How does A good mold factory operate?

When it comes to manufacturing plastic products, having a good mold factory is the key to success. A good mold factory not only ensures the quality of the products but also plays a crucial role in the overall efficiency and cost-effectiveness of the production process. But what exactly makes a mold factory good? How does it operate to deliver the best results? In this article, we will explore the key aspects of a good mold factory and how it operates to meet the demands of modern production processes.

The Importance of Efficiency

Efficiency is at the core of a good mold factory's operations. A good mold factory operates with efficiency in mind at every step of the production process. From designing and prototyping to actual mold production, efficient processes and streamlined operations are essential to ensuring that the factory can meet the demand of its customers. This means that the factory must have the right equipment, skilled workers, and robust quality control measures in place to make sure that the production process runs smoothly and delivers high-quality molds within the specified timeframe.

Efficiency also plays a crucial role in the overall cost-effectiveness of the mold factory. By operating with efficiency, the factory can minimize waste, reduce production times, and optimize resource utilization. This, in turn, helps the factory to be more competitive in the market while still maintaining high-quality standards. A good mold factory understands the importance of efficiency and continuously seeks ways to improve its operations to deliver better results for its customers.

Quality Control Measures

Quality is non-negotiable when it comes to mold production. A good mold factory understands the importance of delivering high-quality molds that meet the exact specifications of its customers. This is why quality control measures are an integral part of the factory's operations. From the initial design phase to the final inspection of the produced molds, stringent quality control measures are in place to ensure that each mold meets the required standards.

A good mold factory invests in state-of-the-art inspection equipment and technologies to perform thorough quality checks at every stage of the production process. This includes using advanced measuring instruments, such as coordinate measuring machines (CMM), optical comparators, and laser scanning systems, to verify the dimensional accuracy of the molds. Additionally, the factory employs skilled quality control personnel who are trained to identify any defects or imperfections in the molds and take corrective actions to rectify them. By implementing robust quality control measures, a good mold factory can guarantee the quality and precision of its molds, earning the trust and confidence of its customers.

Advanced Design and Prototyping Capabilities

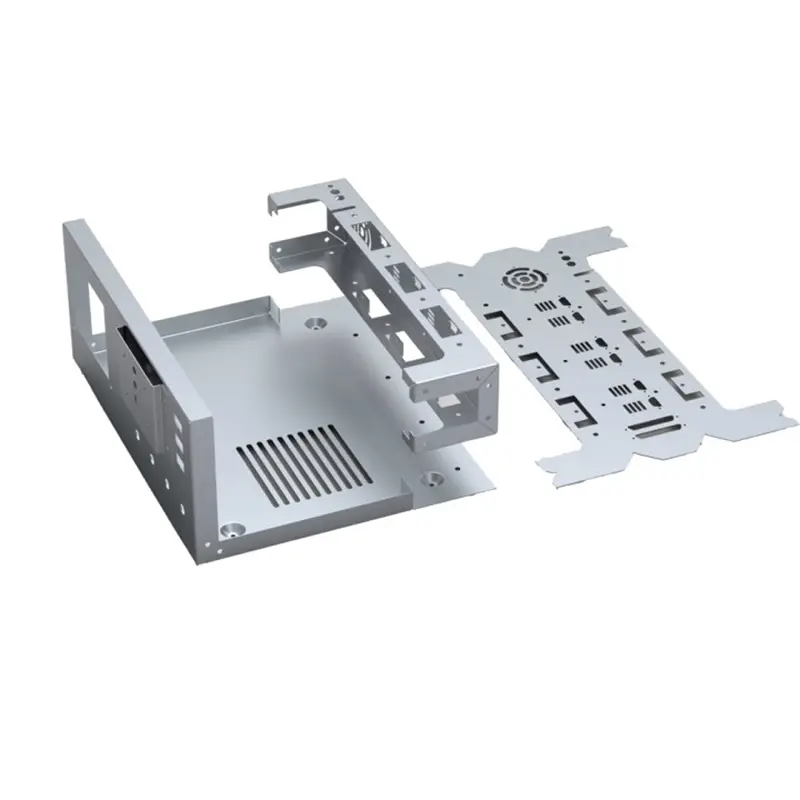

The design and prototyping stage is where the foundation of a high-quality mold is laid. A good mold factory understands the importance of investing in advanced design and prototyping capabilities to bring the vision of its customers to life. The factory utilizes cutting-edge computer-aided design (CAD) and computer-aided manufacturing (CAM) software to design intricate mold geometries with precision and accuracy. This allows the factory to accommodate complex shapes and configurations, as well as to optimize the design for manufacturability and functionality.

In addition to advanced design capabilities, a good mold factory also prioritizes rapid prototyping to validate the design before moving into full-scale production. By utilizing 3D printing and other rapid prototyping technologies, the factory can quickly produce physical prototypes of the molds for evaluation and testing. This not only helps to identify any design flaws early on but also accelerates the overall development process, reducing time-to-market for the final molds. Overall, the advanced design and prototyping capabilities of a good mold factory are essential for delivering innovative and high-quality mold solutions that meet the evolving needs of the market.

Sustainable Manufacturing Practices

In today's environmentally conscious world, sustainable manufacturing practices have become a key consideration for all industries, including mold production. A good mold factory operates with sustainable practices in mind, aiming to minimize its environmental impact and promote resource efficiency. This involves implementing measures to reduce energy consumption, minimize waste generation, and optimize material usage throughout the production process.

One way that a good mold factory promotes sustainability is by utilizing recyclable and eco-friendly materials in its mold production. This not only reduces the environmental footprint of the factory but also contributes to the circular economy by supporting the reuse and recycling of materials. Additionally, the factory may implement energy-efficient technologies, such as LED lighting, high-efficiency machinery, and renewable energy sources, to reduce its overall energy consumption and carbon emissions.

Beyond the production process, a good mold factory also considers the end-of-life disposal of its molds. By designing molds for disassembly and recycling, the factory can ensure that its products have minimal impact on the environment once they reach the end of their useful life. Ultimately, sustainable manufacturing practices are an essential part of how a good mold factory operates, aligning its operations with the goal of preserving the environment for future generations.

Continuous Improvement and Innovation

A good mold factory never rests on its laurels but instead strives for continuous improvement and innovation. It understands that the market is constantly evolving, and staying ahead of the curve is essential to remain competitive. This is why a good mold factory actively invests in research and development to explore new materials, technologies, and techniques that can enhance its mold production capabilities.

Continuous improvement efforts may include implementing lean manufacturing principles to optimize the production process, embracing industry 4.0 technologies to increase automation and connectivity, and adopting new materials and coatings to improve mold performance and longevity. By continuously seeking ways to innovate and improve, a good mold factory can deliver cutting-edge mold solutions that meet the ever-changing needs of its customers and the market.

In summary, a good mold factory operates with efficiency, quality, advanced design and prototyping capabilities, sustainable manufacturing practices, and a commitment to continuous improvement and innovation. By embodying these key aspects, a good mold factory can deliver high-quality molds that meet the demands of modern production processes while maintaining a competitive edge in the market. Whether it's for automotive, consumer goods, medical devices, or any other industry, a good mold factory plays a vital role in bringing innovative plastic products to life.

+86 13433648351