Everything you need to know about plastic molds

Plastic molds are an essential part of many manufacturing processes, allowing for the mass production of plastic products with precision and efficiency. Whether you are new to the world of plastic manufacturing or have years of experience, it's always important to stay updated on the latest information about plastic molds. In this article, we will cover everything you need to know about plastic molds, from their various types to the manufacturing process and maintenance tips.

Types of Plastic Molds

Plastic molds come in various types, each tailored to specific manufacturing needs. Injection molds are one of the most common types, used to produce a wide range of plastic products, including bottle caps, automobile parts, and medical devices. Compression molds, on the other hand, are better suited for manufacturing products with complex shapes and designs, such as fiberglass parts and thermosetting plastics. Another type is the blow mold, ideal for producing hollow plastic products like bottles and containers. Understanding the different types of plastic molds is crucial in determining the best approach for your manufacturing needs.

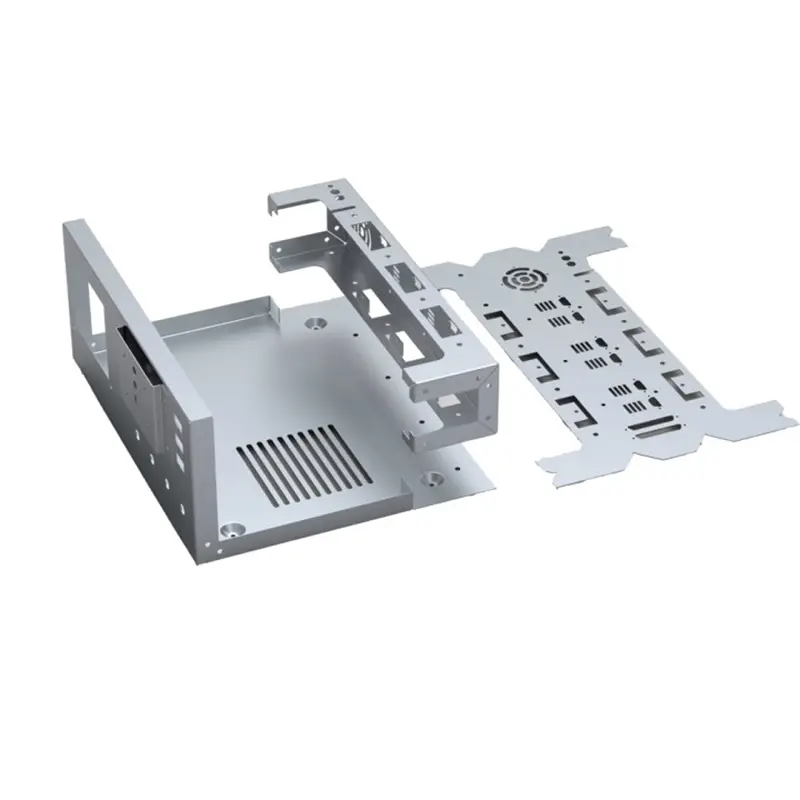

Design and Manufacturing Process

The design and manufacturing process of plastic molds is a complex and intricate task that involves several stages. It starts with the product design, where precise measurements and specifications are outlined to create a mold that will produce the desired product. The next step is mold design and construction, which requires the use of advanced software and equipment to ensure the mold's accuracy and durability. Once the mold is ready, it is tested and fine-tuned to ensure it meets the quality standards. The actual manufacturing process involves injecting molten plastic material into the mold cavity, which is then cooled and hardened to form the final product. Understanding this process is essential for ensuring the quality and efficiency of plastic mold production.

Maintenance and Troubleshooting

Proper maintenance of plastic molds is essential for ensuring their longevity and performance. Regular cleaning and inspection of the molds can help prevent issues such as wear and tear, corrosion, and material buildup. Additionally, troubleshooting common problems such as flashing, sink marks, and warping is crucial for maintaining the quality of the final products. Understanding the best practices for mold maintenance and troubleshooting can save time and resources in the long run.

Quality Control and Inspection

Quality control and inspection are integral parts of the plastic mold manufacturing process. Inspecting the molds for defects, ensuring proper cooling and venting, and fine-tuning the injection process are just some of the factors that contribute to the overall quality of the finished products. Quality control measures such as regular testing and analysis can help identify any issues early on, preventing defective products from reaching the market. Understanding the importance of quality control and inspection is crucial for maintaining the reputation and reliability of your plastic products.

Advancements and Innovations

The world of plastic molds is continuously evolving, with new advancements and innovations constantly being introduced. From the development of advanced materials to the use of 3D printing technology in mold production, staying updated on the latest trends and innovations is crucial for staying ahead in the industry. Understanding these advancements can help manufacturers adapt their processes to improve efficiency, reduce costs, and enhance the quality of their products.

In conclusion, plastic molds play a crucial role in the manufacturing of a wide variety of plastic products. Understanding the different types of molds, the design and manufacturing process, maintenance tips, quality control measures, and the latest advancements is essential for staying competitive in the industry. By staying informed and updated on these key aspects, manufacturers can ensure the efficiency, precision, and quality of their plastic mold production. Whether you are a newcomer or an experienced professional, keeping up with the latest information about plastic molds is essential for success in the industry.

+86 13433648351