Die-Casting Process for Automotive Aluminum Alloy Products

Aluminum alloy products are widely used in the automotive industry for their lightweight and durable properties. The die-casting process is a popular manufacturing method for creating complex automotive aluminum alloy components. This article will explore the die-casting process for automotive aluminum alloy products, including its benefits, applications, and considerations.

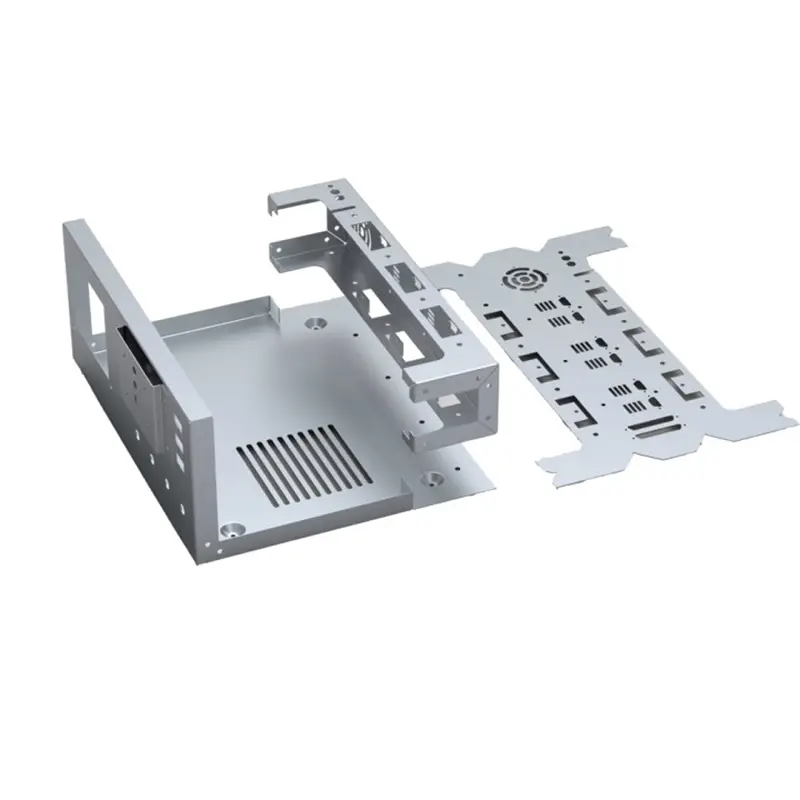

Understanding Die-Casting Process

The die-casting process is a manufacturing technique that involves forcing molten metal into a mold cavity under high pressure. Once the metal cools and solidifies, the mold is opened, and the part is removed. Die-casting is commonly used for mass-producing components with high accuracy and surface finish. In the automotive industry, die-casting is a preferred method for producing aluminum alloy parts due to its cost-effectiveness and ability to create intricate shapes.

The die-casting process begins with the preparation of the mold, which is typically made of tool steel. The mold cavity is designed to replicate the exact shape and features of the desired part. Once the mold is ready, the molten aluminum alloy is injected into the cavity at high pressure, ensuring that it fills all the intricate details of the mold. After the metal solidifies, the mold opens, and the part is ejected, ready for finishing processes such as trimming, machining, and surface treatment.

Benefits of Die-Casting Automotive Parts

Die-casting offers several benefits for producing automotive aluminum alloy products. One of the main advantages is the ability to create complex shapes with high precision. The die-casting process is capable of producing parts with thin walls, fine details, and excellent dimensional stability. This is particularly beneficial for automotive components that require tight tolerances and intricate designs.

Another advantage of die-casting is its cost-effectiveness for mass production. The high-speed production rates and minimal material waste make die-casting a cost-efficient method for large quantities of automotive parts. Additionally, die-cast aluminum alloy components are known for their high strength-to-weight ratio, making them ideal for lightweight automotive applications that require durability and performance.

Furthermore, die-casting provides excellent surface finishes, eliminating the need for additional finishing processes in many cases. The as-cast parts often exhibit a smooth surface with minimal porosity, reducing the need for secondary operations. This not only saves time but also contributes to the overall cost savings in the manufacturing process.

Applications of Die-Casting in Automotive Industry

The automotive industry extensively utilizes die-casting for producing various aluminum alloy components. From engine parts to structural components, die-casting plays a vital role in manufacturing automotive products. Engine blocks, transmission housings, and structural brackets are commonly produced using the die-casting process due to the high strength and lightweight properties of aluminum alloy.

In addition to structural components, die-casting is also used for manufacturing interior and exterior automotive parts. Door handles, mirror housings, and dashboard components are often die-cast to achieve the required shape, strength, and surface finish. The versatility of die-casting allows automotive manufacturers to create a wide range of components with different shapes and sizes to meet the demands of modern vehicle designs.

Considerations for Die-Casting Automotive Aluminum Alloy Products

While die-casting offers numerous advantages for producing automotive aluminum alloy products, there are certain considerations that manufacturers need to take into account. One of the critical aspects is the selection of the right aluminum alloy for die-casting. Different alloy compositions offer varying mechanical properties, corrosion resistance, and heat conductivity, making it essential to choose the most suitable material for the intended application.

Another consideration is the design of the die-cast part. Proper part design is crucial for achieving the desired functionality and manufacturability. Features such as uniform wall thickness, well-designed ribs, and appropriate draft angles are essential for ensuring the integrity of the die-cast part and facilitating the die-casting process.

Furthermore, the optimization of process parameters, including metal temperature, injection pressure, and cooling rate, is important for achieving high-quality die-cast automotive parts. Proper gating and venting design in the mold also play a significant role in minimizing defects and ensuring consistent part quality.

Conclusion

In conclusion, the die-casting process is an integral manufacturing method for producing automotive aluminum alloy products. Its ability to create complex shapes, cost-effectiveness for mass production, and excellent surface finishes make it a preferred choice for automotive manufacturers. With the right considerations in alloy selection, part design, and process optimization, die-casting plays a crucial role in meeting the demanding requirements of the automotive industry for lightweight, durable, and high-precision components. As automotive technology continues to evolve, die-casting will remain a key process for meeting the industry's growing needs for innovative and reliable aluminum alloy products.

+86 13433648351