JSJM is a world-class provider of plastic injection molding services.The target market of our brand has been continuously developed over the years. Now, we want to expand the international market and confidently push our brand to the world.

Introduction

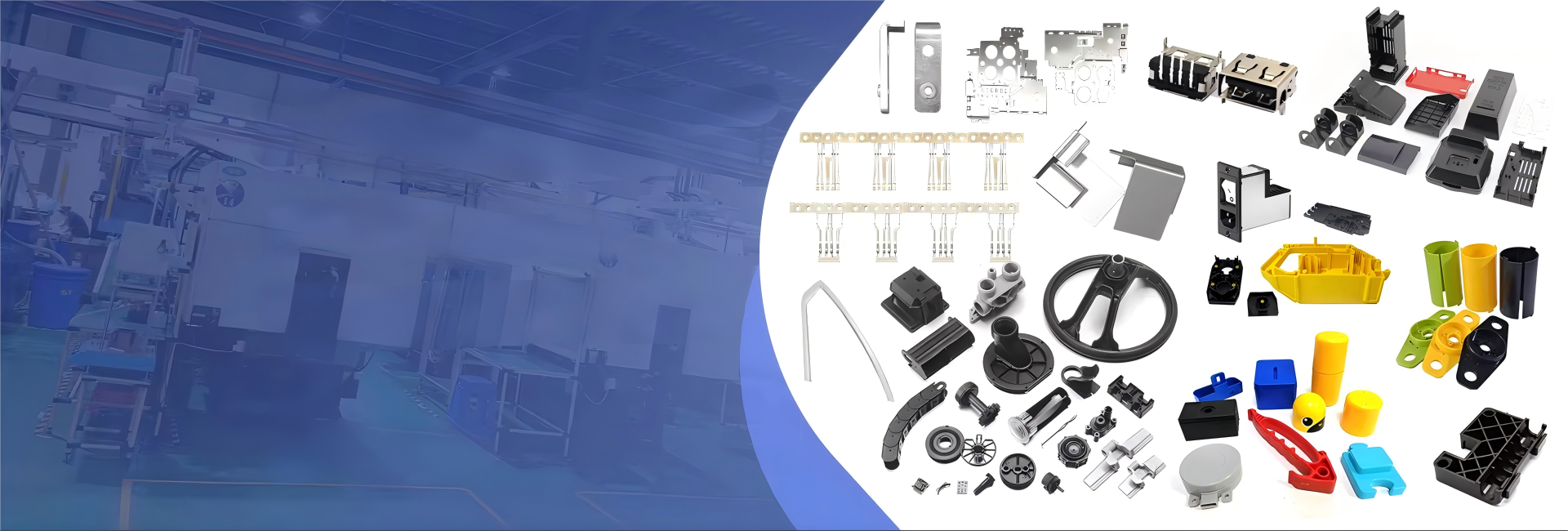

JSJM is a professional Plastic Injection Molding Factory, we also produce Export Plastic Injection Molds. Our other two subsidiaries produce precision stamping metal parts and precision connectors. We have ISO 9001, ISO 14001, ISO45001, IATF 16949 and SGS certification.

Located at Dongguan City, Guangdong Province, JSJM were established in 2010. We have rich experience in Plastic, Metal and Connector industry! Our factories covers an area of more than 40,000 square meters and with more than 500 employees. Each company has its own Engineering Department, Quality Department, Sales Department, Laboratory and so on. Our annual sales are over $30 million!

As the Tier-1 supplier of BYD, the car manufacturer, we have professional project engineers to serve every project! We provide DFM(Design For Manufacturering) report, Moldflow Analysis Report, 3D Mold Drawings, Standard Material Certification (RoHS, Reach, CE, CA65, FDA certification) etc!

Our products include kinds of Precision Structure Parts--Consumer electronics, Mobile phone, Camera bracket, Precision Connector--Waterproof, Automotive and Industrial and Precision Stamping Parts--Terminals, Enclosures, Spring, Shielding enclosures, Automotive and New energy. We also have 10 Assembly Lines! The material we used include ABS, PP, PE, PEEK, PC, TPE, TPU, PEI, POM, PPS, Aluminum, Brass, Stainless Steel, Carbon Steel, Sliver, Gold etc! The surface treatment of the products include Electroplating, Oil spraying, Painting, Oxidation, Metal hardening, etc.

Our customer include BYD, iRobot, Lenovo, Acer, HUAWEI, MI, FOXCONN etc.

We committed to becoming an excellent partner of global consumer electronics and the first-class manufacturer about precision components!

Application

22 Years experience in injection molds and plastic products industry

+86 13433648351